Popular in your industry

Related Searches:

Top categories

About wire wheel brush for drill

Introduction

In the world of metalwork and DIY projects, the wire wheel brush is an indispensable tool. This article serves as your ultimate guide to understanding and using wire wheel brushes for drills. We delve into the types of wire wheel brushes, their applications, and how to choose the right one for your drill. We also provide a step-by-step guide on attaching a wire wheel brush to your drill, safety precautions to observe, effective techniques for use, maintenance tips, and common mistakes to avoid. Whether you're a professional or a hobbyist, this guide will help you maximize the efficiency of your wire wheel brush.

Understanding Wire Wheel Brushes

Wire wheel brushes are wheel-shaped tools with sturdy hubs and metal wire filaments, used for various tasks like cutting, cleaning, deburring, edge blending, polishing, and surface finishing. They are motor-driven and can be used with grinding equipment or CNC machinery. The two basic types are crimped and knotted wire wheel brushes. Crimped wire wheels feature wavy, bent, or pinched filaments, reducing wire fatigue and breakage. Knotted wire wheels, on the other hand, have knots or twists of metal wire, supporting aggressive cutting and absorbing bending and vibrations.

Types of Wire Wheel Brushes

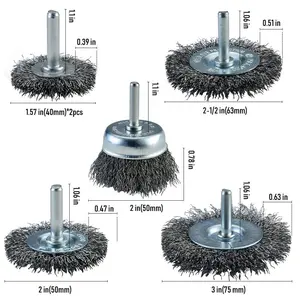

Wire wheel brushes come in various materials including carbon steel, stainless steel, brass, and nylon. Each type has its unique applications and benefits. Brass and nylon brushes are versatile, suitable for most workpieces. Carbon steel and stainless steel brushes, on the other hand, are best paired with specific material types. The choice of wire type should complement your workpiece material. Additionally, wire brushes come in different configurations such as cup, wheel, and end brushes, each offering its own advantages.

Choosing the Right Wire Wheel Brush for Your Drill

When selecting a wire wheel brush for your drill, consider factors like wire type, wire diameter, filament configuration, and trim length. Wire brushes available on Alibaba.com come in carbon steel, stainless steel, and brass. Choose the wire type based on the material you'll be working on. Use fine wires for light-duty jobs and coarse wires for heavy-duty tasks. Wire cup brushes, wheel brushes, and end brushes come in different filament configurations. The trim length refers to the usable filament on the brush. Longer trim lengths are ideal for irregular surfaces, while shorter ones are suitable for more aggressive applications.

How to Attach a Wire Wheel Brush to Your Drill

To attach a wire wheel brush to your drill, first put on safety gear. Insert the brush shank into the drill chuck, which is at the opposite end from the handle. Open the chuck by turning its collar counterclockwise until the brush shank slides in. Lock the brush shank into the chuck by turning the collar clockwise. Ensure the shank stays centered while tightening. Some drills use a chuck key to lock the shank in the chuck. If so, insert the chuck key into the collar's hole, meshing its sprockets with the chuck collar's sprockets. Turn the key clockwise until the brush shank is firmly locked.

Safety Precautions When Using Wire Wheel Brushes

When using wire wheel brushes, safety is paramount. Always inspect brushes for damage, rust, and deterioration before use. Ensure the brush's speed is rated at or above the tool’s rated speed. Use the correct brush for your application and mount it properly. Wear personal protection such as eye and face protection, apron, gloves, safety shoes, and respiratory protection when required. Avoid excessive pressure when using a brush as it can lead to filament breakage and reduced brush life. Lastly, always comply with safety standards and guidelines.

Effective Techniques for Using Wire Wheel Brushes

Wire brushes offer great performance when used correctly. The key to optimal performance is using the right product for the job and following best practices. If you feel the need to press harder to get the results you want, it’s likely you are using the wrong product. Use the finest wire diameter that will do the work without requiring excessive force. This includes using the brush at the proper angle to the workpiece so that the wire tips are doing the work. If you’re not getting the aggression you want, try switching to a thicker wire diameter, a more aggressive knot or potentially a larger diameter brush.

Maintenance and Care for Wire Wheel Brushes

Maintaining your wire wheel brushes is crucial for their longevity. Avoid excessive pressure as it can over-bend the filaments, causing heat build-up and breakage. Instead, opt for a more aggressive cutting action or higher tool speed. Also, use the brush at the highest safe speed for optimal performance. Periodically reverse the direction of rotation for a self-sharpening action that can enhance performance and extend tool life. Remember, proper maintenance can help you avoid rapid dulling and reduced brushing action, ensuring your wire wheel brushes last longer.

Common Mistakes to Avoid

Common mistakes when using wire brushes often involve improper technique or product selection. For instance, using the wrong brush can lead to thrown wires, posing a safety hazard. This typically happens when the brush lacks the necessary aggression for the task, causing the operator to apply excessive force. Another mistake is using the same brush for different materials, which can lead to cross-contamination. For example, using the same brush on carbon steel and stainless steel can contaminate the stainless steel. To avoid these issues, ensure you're using the correct brush for each specific task and material.

Conclusion

In conclusion, wire wheel brushes are versatile tools that can significantly enhance your work efficiency when used correctly. Understanding the different types, their applications, and how to choose the right one for your drill is crucial. Equally important is knowing how to attach them safely to your drill, using them effectively, and maintaining them properly. Avoiding common mistakes can also help ensure your safety and prolong the life of your brushes. With this guide, you're now equipped to make the most out of your wire wheel brushes, ensuring your projects are completed with precision and efficiency.