Popular in your industry

Related Searches:

Top categories

About used pet bottle baling machine

In an era where sustainability is not just a choice but a necessity, businesses are increasingly seeking ways to minimize their environmental footprint. One of the most impactful methods is through the efficient recycling of PET bottles, a common yet significant contributor to plastic waste. This article delves into the world of PET bottle recycling, highlighting the indispensable role of baling machines in enhancing recycling efficiency. From understanding the intricacies of PET bottle recycling to exploring the top used PET bottle baling machines available on Alibaba.com, we provide insights into how your business can optimize its recycling operations and make a positive environmental impact.

Understanding PET Bottle Recycling

PET bottle recycling is a critical process in managing plastic waste, particularly for bottles which are extensively used for beverages and consumer goods. The recycling journey begins with the collection of post-consumer PET bottles, marked with a recycling symbol, and their delivery to material recovery facilities (MRF). Here, they undergo sorting to separate them from other materials. The sorted bottles are then processed into 'bottle flake,' which is transformed into recycled PET (r-PET) through mechanical or chemical recycling methods. Mechanical recycling involves remelting, filtering, and extruding the resin into new PET articles. If the feedstock is impure, chemical recycling is employed to break down the PET into its monomers or oligomers, such as terephthalic acid or ethylene glycol. The recycling process is not uniform and varies based on the waste stream's composition and quality. It's a sophisticated process that includes rigorous sorting, cleaning, and decontamination to ensure the recycled PET is suitable for its next life in various applications.

The Role of Baling Machines in Recycling

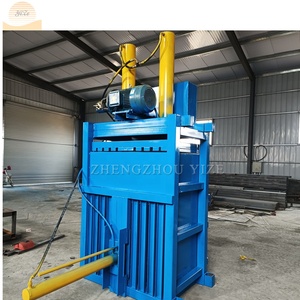

Baling machines play a pivotal role in the recycling industry, particularly in the compaction of recyclable materials into dense, manageable bales. These machines, including those designed for PET bottles, streamline the recycling process by transforming loose, bulky materials into compact shapes that are easier to handle, transport, and store. The efficiency of recycling operations is significantly enhanced through the use of balers, as they help in optimizing space, reducing transportation costs, and minimizing the carbon footprint associated with the recycling of materials. The functionality of balers varies with different models handling a range of materials. Some are equipped with features like automatic tying systems and bale monitoring sensors, which further improve the recycling process. The choice between vertical and horizontal balers depends on the volume of material processed and the specific needs of the recycling operation. Vertical balers are suitable for lower volumes and have a smaller footprint, while horizontal balers are ideal for high-volume recycling and can accommodate continuous feeding, which is essential for larger operations.

Top Used PET Bottle Baling Machines on Alibaba.com

Exploring the range of used PET bottle baling machines available on Alibaba.com reveals a variety of options suitable for different recycling needs. Among the offerings, one can find hydraulic scrap balers and metal press machines that are adept at handling not just PET bottles but also a range of scrap materials. These machines come in various configurations, including vertical and horizontal orientations, to accommodate the spatial and operational requirements of businesses.

Vertical waste presses are particularly noted for their ability to manage paper, cardboard, and PET materials, making them a versatile choice for smaller-scale operations. On the other hand, automatic hydraulic baling presses represent a more advanced solution, capable of dealing with larger volumes and offering increased automation for enhanced efficiency.

For operations focusing on metal scrap, Alibaba-branded horizontal hydraulic baling machines are designed for waste metal recycling. This type of machine underscores the diversity of baling equipment, tailored to specific industry needs. Additionally, the market includes specialized machines like the double crank baling press, which is engineered for baling aluminum cans at a competitive factory price.

Automation in baling processes is a key feature that many businesses seek, and the automated vertical hydraulic baling machines cater to this need. They are built to handle not just PET bottles but also waste paper, enhancing the recycling capabilities of a facility. The presence of compactors like the hydraulic cloth bale press car further expands the range of used baling machines, demonstrating their utility in compressing used clothing and waste paper.

Vertical Baling Machines

In the realm of recycling, vertical baling machines stand as a pivotal component, particularly for compacting used PET bottles. These machines offer a range of pressing forces suitable for various scales of recycling operations. The feed opening sizes ensure that they can accommodate a substantial volume of materials.

The vertical balers' design allows them to produce bales with adjustable heights, ensuring flexibility in bale size and weight, which can range from light to heavy. This adaptability is crucial for businesses looking to optimize their recycling process. The power requirements for these machines indicate their energy efficiency and suitability for continuous operation.

With a baling chamber height that can handle a significant volume and machine weights that ensure stability, these vertical balers are built for durability and consistent performance. The overall dimensions of the machines suggest a compact design, allowing them to fit into various operational setups without requiring excessive space. Such features make these vertical balers an essential asset for businesses aiming to enhance their recycling efficiency with used PET bottles.

Horizontal Baling Machines

Horizontal balers are essential for businesses that handle large volumes of recyclable materials such as PET bottles. These machines are more substantial than their vertical counterparts and require more space. They are designed to be less labor-intensive, despite being more complex and costly.

The horizontal balers come in various models, each suited to different needs. Closed Door Manual-Tie Balers are recommended for cardboard and soft plastics, offering features such as a closed inlet channel and continuous filling. They can produce bales up to 1,400 lbs, with dimensions tailored to the specific model.

Auto-Tie Horizontal Balers provide a high-capacity baling solution with a fully-automatic system for large volumes of waste, making them suitable for operations that require efficiency and ease of use.

For more demanding tasks, our robust line of balers presents versatile options. The Closed Door Balers are capable of handling a range of materials and ensuring optimal bale weights without overstraining the machine. The Two Ram Baler is designed for safety and user-friendliness, capable of managing diverse materials and achieving higher bale weights.

When selecting a horizontal baler, it's crucial to consider the volume of material processed, the types of materials, and the desired efficiency. Open-end balers, for instance, are ideal for higher volumes and bulkier materials, providing a continuous flow and automatic tying, contrasting with the manual tying required by closed-end balers.

Features to Consider When Choosing a Baling Machine

When selecting a baling machine for PET bottle recycling, it's crucial to consider the baler's style and throughput capacity. The style of the baler, whether it's a closed-end manual tie, open-end manual tie, open-end automatic tie, or full-eject manual tie, will affect its suitability for your volume of material, size of material, and the type of material you're processing. The throughput or capacity of the baler is influenced by several factors, including the style of baler, dimensions of the infeed opening, bale height and length, speed of the compression cylinder, and the material characteristics.

The dimensions of the hopper infeed opening are variable and should be matched to your specific needs. Additionally, the power unit's motor and hydraulic pump selection will determine the speed of the compression cycle, which is a critical factor in operational efficiency. For those operating in colder climates or outdoor environments, considerations such as NEMA-4 electrics, special paint, and hydraulic fluid heaters may be necessary to ensure the baler functions correctly under such conditions.

Lastly, the construction of the baler is paramount. Balers built from structural steel are designed to withstand heavy-duty service and offer longevity. The compression force, determined by the cylinder bore size, should align with the required density of your bales. For PET bottle recycling, ensuring that the baler can produce the necessary compression force to create stable and transportable bales is essential for efficient recycling operations.

Advantages of Investing in Quality Baling Equipment

Investing in a baling machine can offer several advantages for businesses that handle recyclable materials like PET bottles. These machines compress waste into compact bales, making it easier to handle, store, and transport. By converting loose materials into bales, businesses can improve the value of their recyclable waste, as baled materials are often more sought after by recycling centers.

The use of baling equipment can lead to significant time savings. These machines can process large volumes of waste without the need for manual preparation, thus freeing up employee time for other tasks. Additionally, the compact nature of baled waste can lead to more efficient use of storage space, reducing clutter and potentially lowering storage costs.

From a financial perspective, baling machines can help reduce transportation costs due to the reduced volume of waste, which translates into fewer trips required for disposal. This not only cuts down on fuel expenses but also minimizes the carbon footprint associated with waste transport.

Furthermore, by enabling businesses to comply with waste management regulations, baling machines can help avoid penalties and improve a company's environmental profile. The compact bales also minimize the risk of contamination, which can enhance workplace health and safety, reducing the likelihood of pest infestations, odors, and fire hazards.

Lastly, baling machines can assist in waste grading, providing valuable data that can inform waste management strategies and potentially open up additional revenue streams from the sale of recyclable materials.

Operational Efficiency and Cost-Effectiveness

Integrating baler machines into waste management processes is a strategic move towards enhancing operational efficiency and cost-effectiveness for businesses of various sizes. These machines are instrumental in compacting waste, which can lead to a significant reduction in the volume of general waste. By optimizing the waste handling process, balers can decrease the volume of materials like plastic, cardboard, and paper by a substantial margin, sometimes up to 90%. This compression not only streamlines waste management but also contributes to a reduction in disposal costs.

Proactive maintenance of baling equipment is essential to ensure continuous and efficient operation. Regular upkeep minimizes the risk of downtime due to machinery failure and can prevent costly accidents. Furthermore, the compacted waste can become a source of revenue, as baled materials are often sought after for recycling purposes. Selling compressed waste to recycling businesses can turn a cost center into a profit-generating activity.

Additionally, the use of baling machines can lead to reduced landfill taxes, a significant expense for companies with large waste outputs. Implementing sustainable waste management practices, such as baling, not only cuts costs but also supports environmental conservation efforts. By diverting waste from landfills and preparing it for recycling, businesses can enjoy both economic benefits and contribute to a greener planet.

Maintenance and Safety Tips for Baling Machines

Maintaining a baler is crucial for ensuring its longevity and efficiency. A clean environment around the baler is as important as the internal cleanliness of the machine. Regular removal of debris and clutter can prevent potential fire hazards and overheating. It's also important to keep the baler's oil free from contamination, as this can lead to metal fragments in the oil, indicating issues with the hydraulic cylinder. Proper filtration or oil changes can mitigate this problem.

Training for operational personnel is essential. Staff should be well-versed in the use of balers, including routine inspections and cleaning, to prevent accidents and equipment malfunction. Having a stock of spare parts for the baler can help avoid operational downtime during unexpected breakdowns. It's advisable to consult with the distributor to understand which parts to keep in inventory.

Regular cleaning and inspection are key to maintaining peak performance levels for balers. Dust and debris can significantly affect the machine's functionality, so establishing a set of inspection guidelines for operators is beneficial. Additionally, adhering to a preventive maintenance schedule is vital. Daily, weekly, and monthly checks can help detect potential issues early on, preventing costly repairs and ensuring the baler operates smoothly.

Conclusion

To encapsulate, the journey of PET bottle recycling is a complex yet rewarding endeavor that can significantly benefit businesses and the environment alike. Baling machines are at the heart of this process, transforming bulky waste into compact, manageable bales, thus optimizing space, reducing transportation costs, and contributing to a lower carbon footprint. With a plethora of options available, from vertical to horizontal balers, and features to consider like throughput capacity and construction, selecting the right baling machine is crucial for operational efficiency. Moreover, investing in quality baling equipment not only streamlines waste management but also offers financial benefits by reducing transportation costs and potentially generating revenue from the sale of recyclable materials. Lastly, regular maintenance and adherence to safety protocols are paramount to ensure the longevity and effectiveness of these machines. By integrating these insights into your business's recycling strategy, you can achieve a harmonious balance between economic efficiency and environmental responsibility.