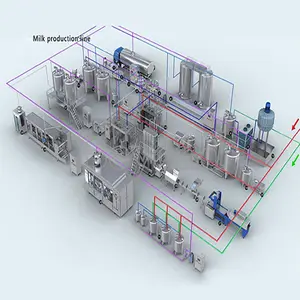

Selecting the right UHT (Ultra-High Temperature) milk machine for your dairy business on Alibaba.com involves considering various factors to ensure you meet your production needs effectively. When browsing the extensive range of UHT machines, focus on the machine's capacity, which can range from small-scale options suitable for boutique dairies to large-scale machines capable of processing thousands of liters per hour for industrial operations.

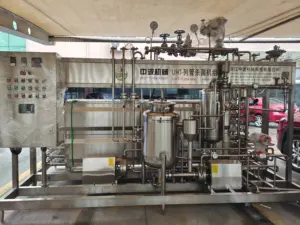

The type of UHT machine also plays a critical role in your selection process. Alibaba.com features a variety of machines, including tubular sterilizers, plate pasteurizers, and continuous flow systems, each designed for specific types of dairy products and operational scales. Assess the compatibility of these machines with your existing production line to ensure seamless integration.

Material and build quality are essential for durability and compliance with food safety standards. Machines constructed with food-grade stainless steel are prevalent on the platform, offering resistance to corrosion and ease of cleaning. Additionally, consider the technological features offered, such as automation, temperature control, and sterilization capabilities, which contribute to the efficiency and safety of the milk processing.

Lastly, while cost is a significant factor, it's important to weigh it against the benefits of efficiency, product quality, and safety enhancements that the machine provides. A cost-benefit analysis can help determine the long-term savings and profitability that the right UHT milk machine can bring to your dairy business.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4