Popular in your industry

Related Searches:

Top categories

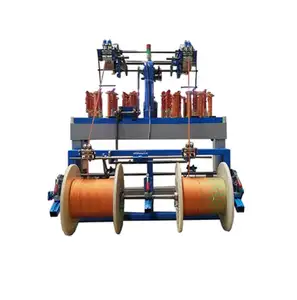

About synthetic rope making machine

Synthetic Rope Making Machine: An Overview

The synthetic rope making machine stands as a cornerstone in the realm of industrial fabrication, playing a pivotal role in the production of various types of synthetic ropes. These machines are engineered to interlace synthetic fibers into ropes that are valued for their strength, flexibility, and resistance to environmental factors. The versatility of these machines allows for the creation of ropes suitable for a myriad of applications, from marine to industrial uses.

Types and Applications

There are several types of braiding equipment designed to meet the diverse needs of the synthetic rope industry. Maypole braiders, for instance, are adept at producing ropes with intricate patterns, often used in decorative or functional capacities. Horn gear braiders, on the other hand, excel in fabricating durable yarns and threads. These machines cater to sectors that demand high-strength outputs, such as sports equipment manufacturing and the creation of industrial-grade ropes.

Features and Materials

A rope braiding machine is characterized by its ability to handle various synthetic materials, including nylon, polyester, and polypropylene. These materials are chosen for their specific properties, such as UV resistance and strength, which are essential for ropes used in outdoor or strenuous environments. The machines themselves are equipped with features that allow for adjustments in tension, pattern, and thickness, ensuring that the end product meets the required specifications.

Advantages of Synthetic Rope Machines

The advantages of using a synthetic rope braider are manifold. These machines offer efficiency in production, consistent quality of the ropes produced, and the flexibility to switch between different types of products with minimal downtime. Additionally, the automation capabilities of modern machines reduce the need for manual labor, thereby increasing safety and productivity in the manufacturing process.

Choosing the Right Machine

Selecting the appropriate industrial rope making machine involves considering several factors, such as the desired output capacity, the types of synthetic materials to be used, and the specific applications of the ropes being produced. Prospective buyers should evaluate the machine's specifications, including gear speeds, power ratings, and overall machine dimensions, to ensure compatibility with their production requirements.

Integration in Industrial Processes

Incorporating a heavy-duty rope making machine into an industrial setting can significantly enhance the production line. These machines are designed to integrate seamlessly with existing manufacturing processes, providing a reliable solution for the continuous production of synthetic ropes. With a focus on durability and adaptability, they are an essential component for industries that rely on synthetic ropes for their products.