Introduction to Slitting Machines

Slitting machines are essential tools in the manufacturing sector, designed for cutting large rolls of material into narrower widths. These machines are pivotal for industries that require precision in slitting materials like paper, film, foil, and various other textiles and composites.

Types and Applications

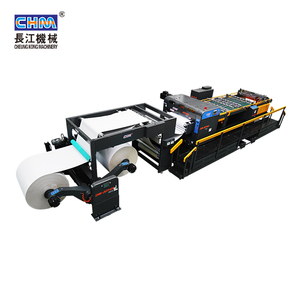

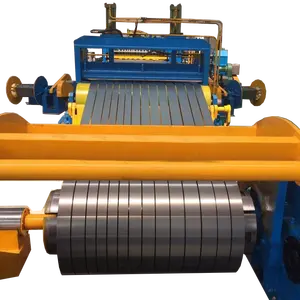

The variety of slitting machines includes models such as the bopp tape slitting machine, non woven slitting machine, and slitter rewinder machine. Each type serves a specific function, from creating biaxially oriented polypropylene (BOPP) tapes to processing non-woven fabrics. The application of these machines spans across packaging, printing, and textile industries, where they are indispensable for efficient production processes.

Features and Performance

Slitting machines are engineered to handle different materials and come with a range of performance capacities. Features may include precise tension control, automatic unwinding, and rewinding capabilities, which contribute to their operational efficiency. The performance of these machines is reflected in their ability to maintain consistent cutting speeds and accuracy, ensuring uniformity in the final product.

Materials and Durability

Durability is a key factor in the construction of slitting machines. Manufacturers use robust materials that withstand the demands of continuous operation. The resilience of these machines translates to a longer lifespan and a reduction in the need for frequent maintenance.

Advantages and Sustainability

One of the main advantages of modern slitting machines is their energy efficiency. Machines such as the mini bopp tape machine are designed to consume less electricity, making them cost-effective for businesses. Additionally, many slitting machines have parts that are recyclable, aligning with eco-friendly practices and contributing to a more sustainable production environment.

Choosing the Right Machine

Selecting the appropriate slitting machine, whether it's a tape slitting machine or a bopp tape cutting machine, depends on the specific needs of a business. Factors to consider include material compatibility, desired cut width, and production volume. Integrating the right slitting machine into your operations can significantly enhance productivity and align with budgetary considerations.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4