Popular in your industry

Related Searches:

Top categories

About rubber powder milling machine

Introduction to Rubber Powder Milling Machines

Rubber powder milling machines are specialized industrial equipment designed to process scrap rubber into fine powder. These machines are a cornerstone in the recycling process of rubber, particularly in transforming automotive tires and other rubber products into a reusable material for various applications. The versatility of these machines allows them to cater to different sizes and types of rubber, making them a valuable asset in the rubber recycling industry.

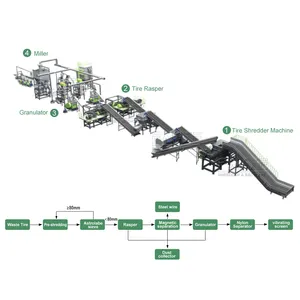

Types and Applications

The rubber milling process involves several types of machinery, each serving a specific function in the production of rubber powder. The primary types include crumb rubber machines, tire shredders, and granulators. Each type plays a crucial role in breaking down rubber into finer particles. These machines are not only used in recycling but also in the production of rubber mats, asphalt additives, and sports surfaces, showcasing their wide range of applications.

Features and Technical Specifications

A typical rubber grinding machine boasts features that enhance efficiency and precision. These include high-torque mechanisms, advanced cooling systems to prevent overheating, and screens that allow for particle size customization. The technical specifications vary, with some machines capable of producing ultra-fine rubber powder, which is essential for high-end applications in various industries.

Materials and Construction

Durability is key in the construction of a rubber powder grinder. High-grade steel is commonly used for the cutting blades and the body to withstand the wear and tear of milling operations. The robust construction ensures longevity and reliability of the machinery, which is crucial for continuous industrial use.

Advantages of Modern Milling Equipment

Modern rubber powder processing equipment is engineered to be energy-efficient and environmentally friendly. The advanced design minimizes waste and maximizes output, contributing to more sustainable production practices. Furthermore, the automation features present in newer models streamline the milling process, reducing the need for manual labor and enhancing safety.

Choosing the Right Machine

Selecting the appropriate rubber powder production machinery is vital for operational success. Factors to consider include the desired particle size, output requirements, and the type of rubber being processed. Suppliers on Alibaba.com can assist in identifying the most suitable machine options, ensuring that the equipment aligns with the specific needs of the production line.