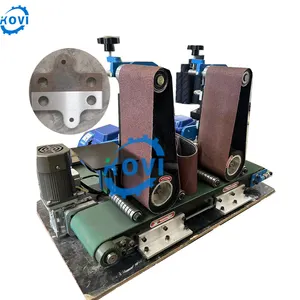

Introduction to Roller Surface Grinding Machines

Roller surface grinding machines are specialized industrial equipment used to grind and finish the surface of various rollers. These precision machines are essential in the manufacturing process where rollers need to have a smooth and flat surface. The grinding process ensures that rollers have the desired surface quality, which is crucial for their performance in various applications.

Types and Features

Roller surface grinding machines come in various types to accommodate different sizes and materials of rollers. Each machine offers specific features such as robust construction, precision engineering, and advanced control systems. These features enable the machine to operate efficiently, delivering consistent and accurate grinding results.

Applications and Materials

The application of roller surface grinding machines spans across numerous industries including printing, metalworking, and paper manufacturing. They are adept at handling a range of materials from metals to rubber, ensuring versatility in their industrial use. The choice of machine often depends on the roller material, as different materials require different grinding techniques.

Operational Advantages

Opting for a roller surface grinding machine brings several operational advantages. These machines are designed to be user-friendly, with some offering automatic operations and others boasting features that allow for easy monitoring of the grinding process. The operational efficiency of these machines can significantly reduce the time and labor involved in roller surface finishing.

Choosing the Right Machine

When selecting a roller surface grinding machine, it is important to consider the specific requirements of the task at hand. Factors such as the size of the rollers, the desired surface finish, and the production volume should guide the selection process. Additionally, the machine's compatibility with different roller materials can be a determining factor in achieving the best grinding results.

Maintenance and Durability

Maintenance is a key aspect of ensuring the longevity and performance of a roller surface grinding machine. These machines are built for durability, but regular maintenance is essential to prevent downtime and extend their service life. Proper care includes routine checks of critical components such as motors and bearings, which are integral to the machine's operation.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4