Popular in your industry

Related Searches:

Top categories

About rebar thread rolling machine

Introduction to Rebar Thread Rolling Machines

Rebar thread rolling machines are essential tools in the construction industry, designed for creating precise threads on reinforcing bars (rebar). These machines are pivotal for ensuring the structural integrity of concrete constructions by facilitating the joining of rebars with threaded connections.

Types and Applications

The rebar thread rolling machine category encompasses various models, each tailored to meet specific threading requirements. From portable units for on-site work to industrial-grade machines for mass production, these machines serve a critical role in manufacturing threaded bars used in building foundations, bridges, and other reinforced concrete structures.

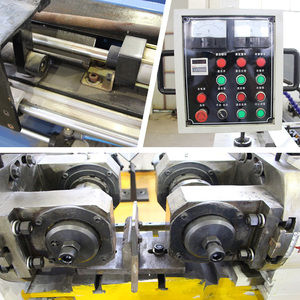

Operational Features

A rebar rolling machine typically operates with a variable speed control, allowing for flexibility and precision in thread production. The integration of advanced technology enables the machine to handle different thread patterns and lengths, which are contingent on the model and die specifications. These machines are designed to accommodate radial and axial threading processes, enhancing their versatility in producing various thread types.

Machine Construction and Durability

Constructed with durability in mind, the rebar thread rolling machine is built to resist impact and vibration, ensuring longevity and consistent performance. The robust motor is engineered for wear resistance, capable of sustaining high-volume production without faltering. Additionally, the inclusion of a power distribution box and gear contributes to the machine's ability to perform high-frequency quenching, streamlining the threading process.

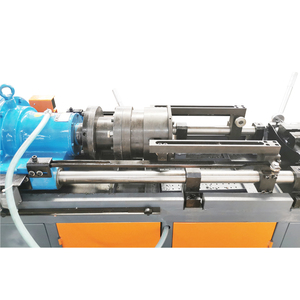

Automation and Efficiency

For those seeking efficiency and ease of use, the automatic rebar rolling machine offers an electro-hydraulic execution function, with options for semi-automatic or fully automatic operations. This adaptability allows users to select the appropriate setting for their threading needs, enhancing productivity with minimal manual intervention.

Additional Features and Advantages

Beyond their primary function, these machines boast features such as self-suction and anti-fouling capabilities, contributing to a cleaner work environment. The low-noise operation is a significant advantage, allowing for uninterrupted work without causing disturbance. With the ability to accommodate a wide array of special molds, the rebar thread rolling machine can produce not only standard threaded rebars but also specialized nails and fasteners, demonstrating its multifaceted utility.

Explore the range of rebar thread rolling machines to discover how these advanced tools can enhance your construction projects with efficiency and precision.