Popular in your industry

Top categories

About polish pad

A polish pad is a kind of disc grinding tool used to polish the surface of the object, which has a strong grinding ability and can quickly polish a variety of workpiece surfaces. As the main accessories of the polishing machine, the polished pad is installed on the polishing machine, with the grinding agent or polishing agent working together to complete the grinding or polishing operation. The connection modes of the polish pad and polishing machine are generally bolt connection and suction cup connection, and the corresponding style can be selected according to whether there is frequent disassembly need. A large amount of dust will be produced in the polishing process, which seriously endangers the workshop's and workers' health. Therefore, a suitable product is also necessary for the work.

Type of polish pad

Different polished panels have different efficiency, properties, and service life. The polish pad for grinder is mainly made of various metal powders after melting and casting. These metal powders have a certain toughness and brittleness and can adapt to the more tough material polishing and grinding work. In addition, the material of the polish pad is also a key point in the selection of products. Generally, due to its good wear resistance and strong stability, chrome polish pad can be a good choice. When mixed into steel, chromium can greatly improve strength, corrosion, wear, high-temperature, and oxidation resistance. And with the good toughness of glass polish pad, it is widely applied in superhard materials, cemented carbide, optical crystals, ceramics, and other hard materials. However, the glass may not withstand long-term use because it is relatively brittle. Simultaneously, hard materials may scratch the object's surface while it is being processed, so sponge or wool can be used.

How to choose a polish pad?

First of all, it is necessary to clarify the purpose and scope of application of the polishing pad, such as whether it is used for rough grinding or fine grinding, as well as the material and shape of the surface to be treated. These factors will determine which type, hardness, and surface structure of the polishing pad to choose. The size and shape of the polishing pad should match the surface of the object being treated to ensure that the polishing pad can fully cover the surface and apply force evenly. At the same time, consider how the polishing pad is fixed and how easy it is to replace. Polishing pads need to have good chemical and mechanical properties, including stability, wear resistance, water resistance, and high-temperature resistance.

How to use a polish pad?

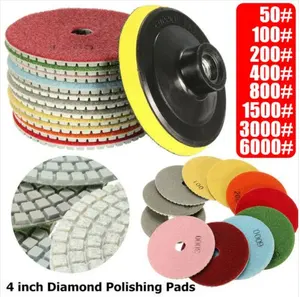

The line of sight should be focused on the edge of the pad and never beyond the corner position to prevent piercing the corner position. When polishing the wheel fender, there are more challenges with smaller areas, and the edge of the pad can do these sides. Choosing the polishing angle should be considered when changing attitudes to different objects. Then, when the polish pad is worn out, press the STOP of the polishing machine, and then remove the polish pad; use polish pad conditioner to maintain pad surface stability. And re-install it in the right direction. Be aware of the danger of the gap; it will cause damage to the pad and the machine.If manual polishing is required, then a hand polish pad is indispensable. Compared with the machine, the workpiece surface's flatness, parallelism, and roughness are not the same, so they need to be considered. The cutting forces represented by different color polish pads are not the same. Before starting the work, please select the rough, fine, and proper polish pad. This work can effectively protect user and avoid waste. After use, remember to clean the machine and use polish pad cleaner to maintain and extend the machine's service life. A clean and tidy working environment will make work safer and more efficient.