Popular in your industry

Related Searches:

Top categories

About plastic sprocket wheel

Exploring the Versatility of Plastic Sprocket Wheels

Plastic sprocket wheels are integral components in various mechanical systems, offering a lightweight yet robust solution for transmitting rotary motion between two shafts where gears are unsuitable. These wheels are specifically designed to engage with a chain or track, ensuring seamless motion transfer in numerous applications.

Types and Applications

The diversity of plastic sprocket wheels is evident in their extensive range of types, such as drive sprockets, idler sprockets, and roller chain sprockets. Each type serves a unique purpose, from driving the system to providing tension and guiding the chain. These sprockets are employed across various industries, from packaging and food processing to agricultural machinery, highlighting their adaptability and importance in modern manufacturing and automation.

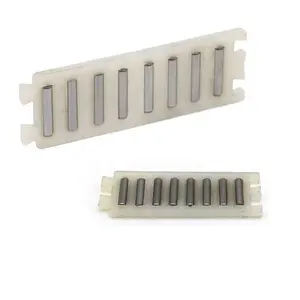

Material Composition and Features

Constructed from durable plastics such as nylon or polyethylene, these sprockets offer resistance to corrosion, a lighter weight alternative to metal counterparts, and reduced noise levels during operation. The material choice also contributes to the sprocket's wear resistance and impact strength, which are crucial for the longevity and reliability of the machinery they are part of.

Design Advantages

The design of plastic sprocket wheels is focused on efficiency and performance. Their non-metallic composition means they do not require lubrication, which can reduce maintenance needs and potential contamination – a significant advantage in industries such as food processing. Additionally, the inherent properties of plastic allow for more flexibility in design, enabling the production of sprockets that can withstand specific environmental stresses or operational demands.

Selection Considerations

When selecting the appropriate plastic sprocket wheel for an application, it is essential to consider factors such as the type of chain it will interact with, the load it must bear, and the environmental conditions it will face. The pitch size, number of teeth, and bore size are also critical specifications that ensure compatibility and optimal performance within a mechanical system.

Integration with Machinery

Integrating plastic sprocket wheels into machinery is a strategic decision to enhance efficiency and reduce operational costs. Their versatility makes them suitable for a wide array of machinery, contributing to the smooth operation of conveyor systems, drive systems, and other chain-driven mechanisms. The selection available on a global platform caters to a broad spectrum of industrial needs, ensuring that businesses can find the exact sprocket configuration required for their specific applications.