Introduction to Plastic Remote Control Toy Car Molds

The realm of manufacturing plastic remote control toy cars is intricate and demands precision engineering, particularly when it comes to the creation of their molds. A plastic remote control toy car mold is a pivotal tool in producing the detailed and durable components that make up these popular toys. This introduction delves into the various aspects of these molds, from their design and types to the materials used and their applications.

Types and Applications

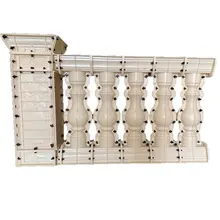

There are several types of molds utilized in the production of remote control toy cars. Injection molds are commonly employed for their efficiency in mass production, allowing for the creation of complex shapes with fine details. These molds are not limited to small items but are also scalable to larger components, such as body panels or frames. The application of these molds extends beyond mere functionality; they are also used to produce decorative elements that enhance the aesthetic appeal of the toys.

Design and Material Considerations

When selecting a mold for plastic remote control toy cars, the design and material are critical factors. The design process begins with a detailed blueprint that ensures the mold will meet the specific requirements of the toy car's design. Materials for the molds vary, with iron being a popular choice for its durability and longevity. However, alternative materials are also available to suit different production needs and specifications.

Features and Advantages

The features of a remote control toy car mold include the ability to produce high-precision parts consistently. One of the main advantages of using these molds is the potential for cost reduction in long-term production through standardization. By standardizing certain elements like lift bars, connection sizes, and clamp slots, manufacturers can streamline the production process and ensure compatibility across various mold designs.

Optimizing Production with Molds

Optimization of production is a key benefit of utilizing a remote control car mold. Manufacturers can work closely with mold providers to refine the mold design, conducting multiple test runs to ensure the final product meets the desired standards. This iterative process helps in fine-tuning the mold for optimal performance and efficiency in the production of remote control toy cars.

Choosing the Right Mold on Alibaba.com

Alibaba.com serves as a bridge between businesses, offering a diverse selection of molds for those in the industry of creating plastic remote control toy cars. The platform facilitates the connection with suppliers who can provide the necessary expertise and resources to find the appropriate plastic remote control toy car mold for your manufacturing needs. With a focus on technical specifications and supplier capabilities, businesses can make informed decisions to enhance their production processes.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4