Popular in your industry

Related Searches:

Top categories

About pe bottle mold

Introduction to PE Bottle Molds

Polyethylene (PE) bottle molds are integral components in the manufacturing of plastic bottles used across various industries. These molds define the precision, quality, and consistency of the final product. PE bottle molds cater to a wide range of applications, from packaging for beverages to household chemicals, offering versatility in design and functionality.

Types and Applications

The versatility of PE bottle molds is evident in their various types, each suited for specific applications. From intricate designs for personal care products to robust containers for industrial fluids, these molds are engineered to meet diverse packaging needs. The application of these molds extends to sectors such as pharmaceuticals, food and beverage, and automotive, highlighting their ubiquitous presence in packaging solutions.

Features and Materials

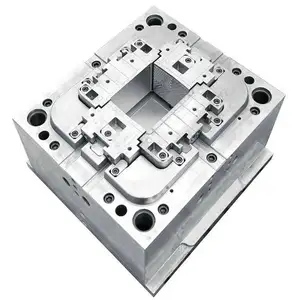

Injection molding technology is commonly employed in the creation of PE bottle molds, allowing for detailed and complex shapes. The materials used in mold making, such as hardened steel or aluminum, are selected based on the production requirements and the desired longevity of the mold. Features such as cooling systems and ejector pins are incorporated to enhance the mold's performance and the efficiency of the bottle production process.

Advantages of PE Bottle Molds

The use of PE bottle molds in production brings several advantages, including scalability and the ability to produce consistent quality bottles with minimal waste. The durability of the molds ensures they can withstand the rigors of mass production, while their precision engineering contributes to the seamless functionality of the bottles they produce.

Customization and Standardization

Customization is a key aspect of PE bottle mold manufacturing, allowing for the creation of unique bottle designs that meet specific brand requirements. Simultaneously, standardization of certain mold elements, such as lift bars and clamp slots, can be optimized to streamline the production process across various mold designs, enhancing operational efficiency.

Choosing the Right PE Bottle Mold

Selecting the appropriate PE bottle mold involves considering the design, material, and specific production needs. Suppliers on Alibaba.com offer a breadth of options and expertise to assist in this selection, ensuring that the mold aligns with the desired output and quality standards. It is essential to engage with these professionals to ensure the mold meets the precise requirements of the intended bottle application.