Polybutylene Terephthalate (PBT) Resin: An Overview

Polybutylene Terephthalate, commonly known as PBT resin, is a thermoplastic engineering polymer that is part of the polyester family. PBT resin is renowned for its excellent balance of properties, including mechanical strength, electrical insulation, heat resistance, and chemical stability. This material is widely utilized in various industries, offering versatility in applications ranging from electronic components to automotive parts.

Types and Forms of PBT Resin

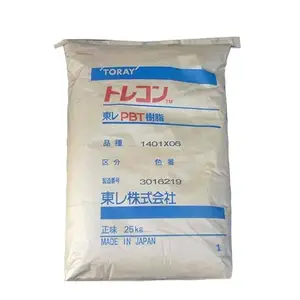

The diversity of PBT resin is evident in its various forms and types. It is commonly available in granular or pellet form, catering to different manufacturing processes. The resin can be reinforced with glass fibers, with common types being PBT GF30 and PBT GF20, where the numbers indicate the percentage of glass fiber content. These reinforcements enhance the material's strength and thermal properties, making it suitable for more demanding applications.

Applications of PBT Resin in Industry

PBT resin is extensively used in the electronics industry due to its excellent insulating properties. It is a preferred material for connectors, switches, and other components. In the automotive sector, PBT's durability and heat resistance make it ideal for under-the-hood parts, as well as interior and exterior trims. The material's ease of molding and robustness also make it suitable for injection molding processes, which are commonly employed in the production of high-precision parts.

Features and Advantages of PBT Resin

The features of PBT resin contribute to its popularity in various applications. Its low moisture absorption rate ensures dimensional stability, while its resistance to solvents and chemicals makes it a durable choice for many environments. Additionally, PBT resin's thermal properties allow it to perform consistently in a wide temperature range. The material's inherent flame retardancy and electrical insulation capabilities are also beneficial for safety-critical components.

Material Composition and Sustainability

PBT resin is a polymer made from terephthalic acid and butanediol. This composition contributes to its recyclability, aligning with the growing demand for sustainable materials in manufacturing. The potential for reusing and recycling PBT resin helps industries reduce their environmental footprint, making it a forward-thinking choice for eco-conscious businesses.

Choosing the Right PBT Resin

Selecting the appropriate PBT resin for a specific application requires consideration of the material's properties and the requirements of the end product. Factors such as mechanical strength, thermal stability, and electrical insulation should be evaluated to ensure the chosen PBT resin meets the performance criteria. While Alibaba.com does not endorse any particular brand or type, the platform offers a comprehensive range of PBT resin options to cater to diverse industrial needs.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4