Popular in your industry

Related Searches:

Top categories

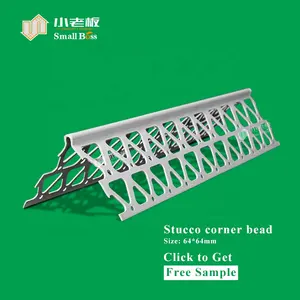

About paper faced corner bead

A paper faced corner bead is an essential component in modern construction, particularly in the finishing stages of drywall installation. This product is designed to provide a clean, sharp edge at the corners of walls, ensuring a professional finish and added durability. The paper faced corner bead is a hybrid material, combining the strength of metal with the smooth finish of paper, which can be easily painted over or finished with drywall compound.

Types and Materials of Paper Faced Corner Beads

The paper faced corner bead market offers a variety of types to suit different construction needs. From the standard drywall paper corner bead used in residential projects to the paper faced metal corner bead for commercial applications, each type is tailored for specific scenarios. The 10 ft paper faced super wide outside corner bead is designed for expansive areas, providing continuous protection without the need for multiple pieces. The paper faced inside corner bead is another specialized type, designed to fit snugly into interior corners and angles. These variations ensure that whether the project is a small home renovation or a large commercial build, there is a corner bead that fits the requirements.

Structural Design and Application

The paper faced corner bead is ingeniously designed to combine durability with ease of use. The core of the bead is typically made from a sturdy material like galvanized steel, which provides the necessary strength to withstand impacts and pressure. This metal core is enveloped by a layer of paper that not only facilitates a strong bond with joint compound but also offers a smooth surface for finishing. The bead's structure is such that it can be applied to both straight edges and curves, making it a versatile choice for a variety of wall configurations. Its application in settings ranging from drywall corners in homes to more complex structures in commercial buildings showcases its adaptability and effectiveness in providing a durable finish.

Materials and Properties

The materials selected for paper faced corner beads are pivotal in their performance. Aluminum alloy is chosen for its lightweight nature and resistance to corrosion, making it suitable for wet areas like bathrooms and kitchens. Galvanized steel is favored for its toughness and ability to hold its shape over time, providing a lasting solution for high-traffic areas. The paper coating is a crucial component, often treated to be mold-resistant and to provide a superior bond with drywall compounds. This combination of materials results in a product that not only performs well but also supports green building standards by using sustainable and often recyclable materials.

Business Usages and Applications

Paper faced corner beads are widely used across various industries. In the hospitality industry, they contribute to the longevity and aesthetic appeal of the interiors, which is crucial for creating a welcoming environment for guests. In commercial real estate, the precision and durability of these beads can influence leasing rates and property values. They are also used in the healthcare sector, where maintaining clean lines and surfaces is essential for hygiene and cleanliness. The application of these beads in different settings illustrates their versatility and the value they add to any construction project by enhancing both the appearance and durability of wall corners.

Functions of Paper Faced Corner Beads

The primary function of paper faced corner beads is to fortify and define the edges of drywall at corners, which are prone to damage. They are designed to absorb shocks and provide a consistently sharp edge, which is crucial in both aesthetic and practical terms. The paper facing simplifies the finishing process, as it is compatible with the drywall compound and can be easily feathered out to create a smooth, inconspicuous transition. This functional aspect is critical in ensuring that the final wall finish is both visually appealing and structurally sound.

Features of Paper Faced Corner Beads

The features of paper faced corner beads that set them apart include their composite structure, which allows for a combination of flexibility and strength. The paper layer is designed to prevent shrinkage and cracking, ensuring that the finish remains intact over time. Additionally, the beads are available in various lengths and profiles, accommodating a wide range of design specifications and reducing the need for on-site modifications. These features make the beads a go-to choice for contractors looking for a reliable and high-quality finish.

Benefits of Paper Faced Corner Beads

The use of paper faced corner beads brings numerous benefits to construction projects. They significantly reduce the time required for corner finishing, which can be one of the more time-consuming aspects of drywall installation. The beads also minimize the need for repairs and touch-ups post-installation, thanks to their robust construction. For the end-user, this translates to lower maintenance costs and a longer lifespan for their walls. The aesthetic benefits are equally important, as these beads help achieve a level of finish that is smooth, clean, and professional.

How does the paper faced corner bead contribute to the durability of drywall installations?

The paper faced corner bead plays a crucial role in the longevity of drywall installations. By reinforcing the vulnerable corners where sheets of drywall meet, these beads prevent the common issue of corner dents and damage. The metal core provides structural integrity, while the paper facing ensures a bond with the drywall compound for a durable finish that can withstand the rigors of daily life.

What are the considerations when choosing the right paper faced corner bead for a project?

When selecting a paper faced corner bead, it's important to consider the material compatibility with the existing structure, the design style of the building, and the specific application. The bead's size and flexibility should match the project's requirements, and the color should be appropriate for the intended finish. Additionally, the environmental impact and the availability of after-sale services can influence the decision-making process.

How can one ensure the optimal application of paper faced corner beads during installation?

To ensure the optimal application of paper faced corner beads, it is essential to prepare the drywall corners properly, apply the right amount of joint compound, and firmly press the bead into place. Ensuring that the bead is straight and fully embedded in the compound is crucial. Subsequent layers of compound should be applied thinly and evenly, with adequate drying time between applications, followed by thorough sanding for a smooth finish.