Popular in your industry

Related Searches:

Top categories

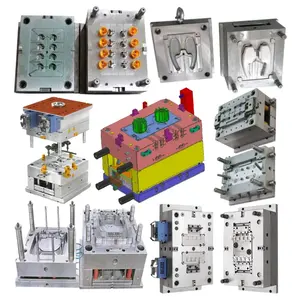

About motorcycle molding machine

Introduction to Motorcycle Molding Machines

Motorcycle molding machines are specialized equipment used in the manufacturing of plastic components for motorcycles and various other industries. These machines utilize the plastic injection molding process to produce parts with precision and consistency. Designed to cater to a range of applications, these machines are integral in producing items from consumer electronics to automotive components.

Types and Applications

The versatility of motorcycle molding machines extends to their ability to manufacture a wide array of products. Not limited to motorcycle parts, these machines are also pivotal in creating packaging materials, PVC pipe fittings, and thin-wall containers. Their adaptability makes them suitable for industries such as pharmaceuticals, food and beverage, and consumer electronics.

Features and Materials

A key feature of these machines is the special screw design that enhances plasticizing capabilities, improving both shot weight and speed. The materials used in the construction of these machines, such as the steel bush in the clamping unit, are chosen for their durability and wear resistance. This design consideration ensures a reduction in maintenance needs, particularly in lubrication costs.

Advantages of Modern Molding Machines

Modern motorcycle molding machines come equipped with a single-cylinder system and servo-valve, enabling a swift response rate during operation. The clamping force of these machines can range significantly, allowing them to withstand various external machining forces. This capability ensures that the machines can maintain high precision in the molding process, resulting in a lower rate of defective outputs.

Technical Specifications

The technical prowess of a motorcycle molding machine is evident in its clamping force, which varies from 2,000 kN to 13,000 kN, catering to different sizes of preforms. The construction of these machines is such that they provide the exact clamping force needed for specific tasks, enhancing the efficiency of the molding process.

Choosing the Right Machine

Selecting the right motorcycle molding machine involves understanding the specific requirements of your production line. These machines are capable of transforming plastic granules into precise dimensions, essential for high-accuracy applications. When considering an investment in a molding machine, it is crucial to assess the machine's capacity to meet your production needs.