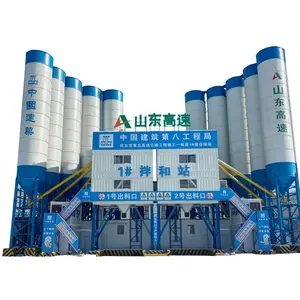

Liquid Mixing Station Overview

A liquid mixing station is an integral component in various industrial processes where the combination of different liquids is essential. This equipment is designed to facilitate the homogeneous mixing of liquids to achieve a consistent product quality. The stations vary in size, design, and functionality, catering to a wide range of industries from pharmaceuticals to food and beverage production.

Types and Applications

The diversity of liquid mixing stations is evident in their applications. Batch mixers, continuous mixers, and in-line mixers are among the common types, each serving distinct mixing processes. Batch mixers are suitable for mixing a predetermined volume of liquid, while continuous mixers are used for large-scale production that requires a constant flow of materials. In-line mixers provide rapid mixing and are often used in systems where space is at a premium.

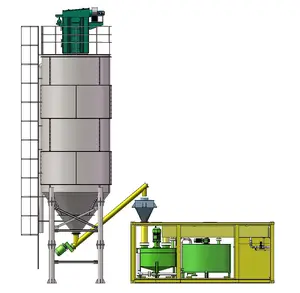

Features and Materials

A liquid mixer is often characterized by its robust construction and the use of corrosion-resistant materials such as stainless steel. Advanced features may include digital controls, variable speed options, and automated dosing systems. The choice of material and features directly impacts the mixer's efficacy and longevity, especially when dealing with abrasive or corrosive substances.

Advantages of Modern Mixing Solutions

Modern liquid mixing solutions offer enhanced precision and efficiency. They are engineered to reduce manual intervention, thereby minimizing the risk of human error. The precision in control also ensures consistent product quality, which is crucial in industries where product standards cannot be compromised.

Selection Considerations

When selecting a liquid mixing system, it is important to consider the viscosity of the liquids, the required mixing speed, and the volume of production. These factors will determine the most suitable type of mixer and its specifications. Additionally, the ease of cleaning and maintenance should be considered to ensure compliance with industry standards and regulations.

Procuring Liquid Mixing Stations on Alibaba.com

Alibaba.com serves as a marketplace to connect buyers with a plethora of suppliers offering various liquid mixing equipment. The platform enables users to efficiently search and compare different models and features to find the right fit for their business needs. With detailed product descriptions and supplier profiles, buyers can make informed decisions without the pressure of time constraints.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4