Popular in your industry

Top categories

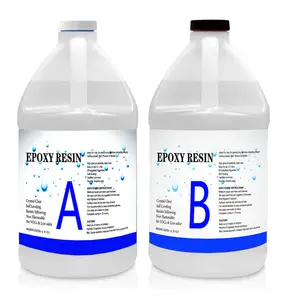

About laminating epoxy resin

Laminating Epoxy Resin: An Overview

Laminating epoxy resin is a versatile compound used extensively in various industries for its strong adhesive properties and durability. This resin is a two-component system, consisting of the resin itself and a hardener, which when mixed, creates a robust material known for its excellent bonding and protective qualities.

Types and Applications

There are several types of laminating epoxy resins catering to different needs. Marine laminating epoxy is formulated to withstand harsh marine environments, making it ideal for boat and shipbuilding. Carbon fiber laminating epoxy resin is designed for the automotive and aerospace industries, where strength-to-weight ratio is critical. For the electronics industry, high temperature laminating epoxy ensures performance under extreme heat. In construction, epoxy resin for laminating wood provides a strong, waterproof bond for wooden structures.

Features and Advantages

The primary feature of laminating epoxy resin is its superior bonding strength. It is also noted for its clear laminating epoxy variant, which offers a transparent finish, ideal for artistic and furniture applications. These resins are resistant to weather, UV rays, and hydrolysis, ensuring longevity and durability in various environmental conditions. The versatility of laminating fiberglass with epoxy demonstrates its capacity to bond with a range of materials, providing flexibility in its use.

Materials and Composition

Laminating epoxy resins are composed of base materials such as silicone, polysiloxane, and various fillers that contribute to their stability and bonding properties. Innovations like dipoxy 2k 700 epoxy resin and hardener showcase advancements in the field, offering users a reliable solution for their laminating needs. The composition of these resins is engineered to cater to specific requirements, such as layup and laminating epoxy resin for layering composites in manufacturing.

Selection and Usage Considerations

When selecting a laminating epoxy resin, it is crucial to consider the specific requirements of the project. Factors such as cure time, with products like dipoxy 2k 700 cure time being a critical consideration, and temperature tolerance must be matched to the application. It is also important to consider the material compatibility, such as laminating glass with epoxy or using pro marine laminating epoxy for nautical applications.

Environmental and Safety Aspects

Safety and environmental impact are important considerations when working with laminating epoxy resins. Users should ensure proper handling procedures are followed and look for products that align with environmental standards. Suppliers on Alibaba.com offer a range of laminating epoxy resin options that cater to these concerns, providing peace of mind for users and industries alike.