Popular in your industry

Related Searches:

Top categories

About industrial gripper robot arm

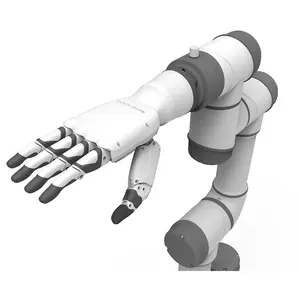

Introduction to Industrial Gripper Robot Arms

Industrial gripper robot arms represent a transformative innovation in the realm of automation and manufacturing. These sophisticated devices are engineered to streamline complex tasks, such as material handling and assembly processes, by providing precise and consistent manipulation of objects. Their integration into production lines has revolutionized the efficiency and safety standards of industrial operations.

Types and Applications

The versatility of industrial robot grippers is evident in their various types, each suited to specific tasks. For instance, scara robot grippers are known for their speed and precision in pick-and-place operations, making them ideal for electronics assembly. On the other hand, heavier-duty grippers are utilized in automotive manufacturing for their ability to handle large and heavy components with ease. Across industries, these robotic arms are indispensable for tasks that require the dexterity and reliability that human labor cannot consistently provide.

Features and Materials

An industrial gripper robot arm is characterized by its features, which may include multiple axes of rotation, force sensing capabilities, and advanced control systems. The materials used in their construction, such as high-strength alloys and composites, are selected for durability and performance, ensuring the longevity and reliability of the equipment in various industrial environments.

Advantages of Automation

Incorporating an industrial gripper robot arm into a production line can significantly enhance operational efficiency. These robotic systems are designed to operate continuously without fatigue, reducing cycle times and increasing throughput. Moreover, they contribute to workplace safety by undertaking tasks that would be hazardous for human workers, thereby reducing the incidence of workplace injuries and related disorders.

Selection Considerations

Selecting the right robot gripper manufacturers involves evaluating several critical factors. The payload capacity is paramount, as it determines the weight and size of objects the gripper can handle. Additionally, the range of motion required, including lifting distance and the degree of articulation, must align with the intended application. Power source is another consideration, with options including pneumatic, electric, and hydraulic systems, each offering different benefits in terms of speed, force, and control.

Discovering Solutions on Alibaba.com

For businesses seeking to enhance their automation capabilities, Alibaba.com serves as a gateway to a wide array of industrial gripper robot arms. The platform connects buyers with a diverse selection of solutions, tailored to meet various operational demands without endorsing specific brands. Alibaba.com facilitates the exploration of advanced robotic systems, enabling businesses to find the right tools to elevate their production capabilities.