Popular in your industry

Related Searches:

Top categories

About cut roll

Introduction to Cut Roll Machinery

The term cut roll refers to specialized equipment used in the production of paper products such as toilet paper, napkins, and other disposables. This machinery is integral to the operations of various industries, from hospitality to manufacturing plants, and paper processing sectors. Understanding the intricacies of these machines is essential for businesses looking to streamline their paper product manufacturing processes.

Types and Applications

Cut roll machinery comes in diverse forms to cater to different production needs. From compact units suitable for small-scale operations to robust systems designed for high-volume production, the range is extensive. These machines are adept at producing a variety of paper products, including cut sushi roll wrappers, serviettes, and other tissue products. The versatility of cut roll equipment makes it a valuable asset in settings such as large hotels and paper processing industries.

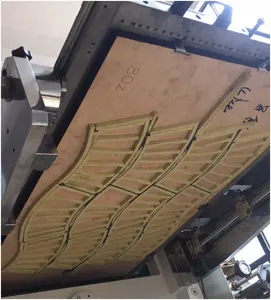

Features and Functionality

A typical cut roll machine encompasses multiple features such as embossing, slitting, folding, and counting. The embossing process can be executed using different patterns, with options like steel to steel or steel to rubber embossing. Advanced models are equipped with color printing capabilities, enhancing the aesthetic appeal of the final product. Furthermore, these machines are designed to stack output papers efficiently, ensuring orderly production.

Technical Specifications

The technical specifications of cut roll machinery vary based on the model and intended use. Smaller machines may weigh approximately 1,000kgs and utilize power upwards of 3kw, with production capacities ranging from 70 to 80 pieces per minute. Larger variants, suitable for mass production, can weigh over 3,000kgs and boast capacities of around 3 tons per day. The driving systems of these machines are either gear or chain-driven, with many incorporating fully automated processes and automatic oil lubrication for efficiency and longevity.

Innovations in Cut Roll Technology

Innovation in cut roll technology has led to the integration of photoelectric technology, which monitors machine activities and alerts operators to paper shortages or operational issues. Additionally, these machines often come with an air compressor pneumatic system and are managed via a PLC control panel, which automates the production process and reduces the need for constant human intervention.

Choosing the Right Cut Roll Equipment

Selecting the appropriate cut roll equipment involves considering production scale, desired features, and the specific types of paper products being manufactured, such as maki cut roll or standard napkins. Prospective buyers should assess the full range of machinery options available on Alibaba.com to find a unit that aligns with their operational requirements and production goals.