Popular in your industry

Top categories

About custom plastic cup molding

Introduction to Custom Plastic Cup Molding

Custom plastic cup molding is a specialized manufacturing process tailored to create precise plastic components for a variety of uses. This technique is pivotal in producing high-volume, consistent products for businesses across multiple industries. By leveraging advanced mold fabrication services, custom plastic cup molding facilitates the creation of both intricate small items and larger, more decorative pieces.

Types and Applications of Plastic Cup Molds

The versatility of injection molding services extends to producing diverse types of molds, including those for functional items or aesthetic enhancements like bolection molds. These molds are not just limited to cups but can be adapted for various applications, ensuring that the end product meets the specific needs of different sectors, from food and beverage to medical and automotive industries.

Material Selection in Mold Making

Selecting the right material for a mold is crucial in the custom molding process. Options range from durable iron to innovative composites, each offering distinct advantages. The choice of material impacts the mold's longevity, the finish of the produced cups, and the overall efficiency of the production cycle.

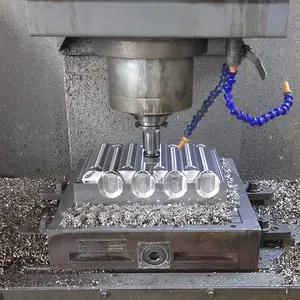

Customization and Precision in Mold Design

The journey to a perfect custom plastic cup begins with a design that is meticulously brought to life through expert mold making. The process includes crafting test samples to ensure the mold's precision, reflecting the importance of custom mold design in achieving the desired outcome. This attention to detail ensures that each mold meets the exact specifications required for the product's function and aesthetic.

Cost Efficiency in Production

Efficiency is key in production, and custom plastic cup molding offers opportunities to standardize certain mold elements. By harmonizing features like lift bars, connection sizes, and clamp slots, businesses can streamline their operations, leading to reduced production costs and enhanced compatibility across various molding projects.

Finding the Right Molding Partner

Alibaba.com stands as a gateway to connect with seasoned processors for all custom plastic cup molding requirements. The platform's extensive network enables businesses to find the right partners to bring their custom plastic products to life, ensuring a match with suppliers who can meet the specific needs of their molding projects.