Popular in your industry

Related Searches:

Top categories

About copper briquettes making machine

Introduction to Copper Briquettes Making Machines

Copper briquettes making machines are innovative solutions for recycling and waste management, transforming metal scraps into valuable briquettes. These machines are designed to process a variety of materials, including copper filings, shavings, and powders, converting them into compact, easy-to-handle forms. The briquetting process not only facilitates the efficient storage and transportation of metal waste but also contributes to environmental sustainability by reducing the need for mining new resources.

Types and Applications

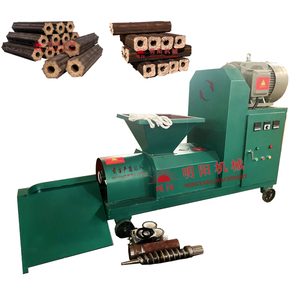

The versatility of copper briquettes making machines allows for their use in conjunction with other equipment such as wood crushers, sawdust dryers, and carbonization furnaces to establish a full charcoal production line. These machines are adept at handling bio-waste like sawdust and agricultural residues, making them suitable for a broad range of applications in the recycling and energy production sectors.

Technical Specifications and Features

Advanced briquetting machinery employs hydraulic systems to compress materials with a size range of 3mm to 5mm into dense briquettes, achieving densities from 1 to 1.4g/cm3. The process is automated, ensuring consistent feeding of raw materials and discharge of finished briquettes. Heat and pressure work in tandem to produce hardened briquettes, with some machines boasting up to 22kw of power for bio-waste and 30kw to 55kw for metal chips. The machine's design accommodates various moisture contents, typically between 8% to 12%, to cater to different material types.

Product Dimensions and Output Capacity

The output capacity of these machines varies, with smaller models producing around 140kg/h and larger ones capable of up to 3,000kg/h for materials like coal. Briquettes come in diverse shapes and sizes, from cylindrical to hexagonal, with diameters ranging from 30mm to 90mm. The adaptability of the copper briquettes making machine ensures that it meets the needs of various production scales and requirements.

Advantages of Using Copper Briquettes Making Machines

Utilizing a copper briquettes making machine offers numerous advantages. It enables the conversion of waste into a profitable commodity and promotes the circular economy by repurposing metal waste. Additionally, the compactness of briquettes reduces logistical challenges associated with the transportation and storage of loose materials. The environmental impact is also mitigated as the need for new material extraction is lessened, aligning with global sustainability goals.

Choosing the Right Machine

Selecting the appropriate copper briquettes making machine is crucial for operational efficiency. Prospective buyers should consider the type of waste material, desired briquette size and shape, and production capacity when browsing the extensive selection available on Alibaba.com. While exploring the options, it is important to assess the technical specifications and compatibility with existing production lines to ensure a seamless integration.