Popular in your industry

Related Searches:

Top categories

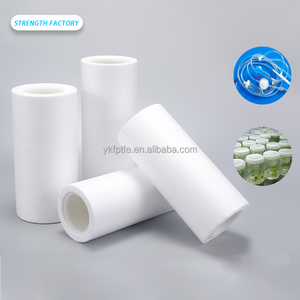

About chemical resistance ptfe tape

Understanding Chemical Resistance PTFE Tape

Polytetrafluoroethylene, commonly known as PTFE, is a synthetic fluoropolymer with exceptional chemical resistance, making chemical resistance PTFE tape a go-to solution in numerous industries. This introduction delves into the unique properties and applications of PTFE tape, a product that stands out for its durability and versatility.

Properties and Applications

PTFE tape is renowned for its ability to withstand a wide range of chemicals, making it an ideal choice for sealing and protecting joints in various piping systems. Its applications extend from plumbing to complex industrial environments where chemical exposure is a concern. The tape's inherent non-stick nature also facilitates a clean release from surfaces, which is essential in manufacturing processes involving adhesives and sealants.

Types and Features

The market offers various types of PTFE thread seal tape, each tailored to specific requirements. Some variants are designed for heavy-duty applications, offering enhanced tensile strength, while others are more suitable for high-purity systems, minimizing the risk of contamination. Features such as temperature stability, from cryogenic up to several hundred degrees Celsius, and a low friction coefficient, contribute to the tape's adaptability across different scenarios.

Material Composition and Advantages

The molecular structure of PTFE grants it a set of advantages that are hard to replicate with other materials. Its resistance to weathering and UV exposure ensures longevity, while its flexibility allows for ease of application around complex shapes and surfaces. The non-conductive nature of PTFE seal tape also makes it safe for use in electrical applications, providing an additional layer of user safety.

Selection and Sourcing on Alibaba.com

Choosing the right PTFE tape for chemical resistance is crucial for ensuring the integrity of your project. Alibaba.com's platform facilitates this process by offering a diverse array of PTFE tape options. Buyers can source PTFE in different forms, such as tape, rod, or powder, to meet their specific manufacturing or maintenance needs. It's important to consider factors like the chemical environment, temperature range, and mechanical requirements when selecting a PTFE tape.

Environmental and Economic Considerations

In today's eco-conscious market, the environmental impact of products is as important as their economic viability. PTFE tape is an environmentally friendly option due to its long service life and inertness, reducing the need for frequent replacements and minimizing waste. Economically, the efficiency of PTFE adhesive tape in preventing leaks and maintaining seals can save costs associated with downtime and repairs, making it a cost-effective solution for long-term use.

Incorporating chemical resistance PTFE tape into your operations can significantly enhance the performance and reliability of your equipment. Alibaba.com provides a comprehensive platform to connect with suppliers, ensuring you find the PTFE tape that meets your specific requirements.