Related Searches:

Top categories

About charcoal production kiln

Introduction to Charcoal Production Kilns

Charcoal production kilns are specialized devices designed for the transformation of organic materials into charcoal through a process of pyrolysis. These kilns come in various configurations, including traditional charcoal kilns, drum kiln charcoal making units, and more advanced retort kiln models. Each type caters to different production scales, from small charcoal kiln designs suitable for local artisans to industrial charcoal kiln systems for commercial operations.

Types and Applications of Charcoal Kilns

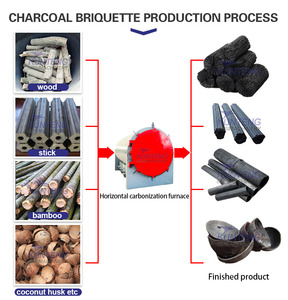

The diversity of charcoal kilns available includes the portable charcoal kiln, which offers mobility and convenience for small-scale producers. On the other end of the spectrum, the commercial charcoal retort allows for larger-scale production with increased efficiency. These kilns are used to produce charcoal from a variety of materials, such as wood, coconut shells, and maize cobs, which are then utilized in cooking, industrial processes, or as a fuel source in heating systems.

Features and Materials

A charcoal production kiln is designed to maximize the carbonization of feedstock while minimizing waste. Materials used in the construction of these kilns include heat-resistant metals and insulating materials that ensure durability and optimal performance. Innovations like the adam retort kiln have improved the efficiency of the carbonization process, reducing the environmental impact of charcoal production.

Advantages of Modern Charcoal Kilns

Modern kilns, such as the retort kiln charcoal production units, offer several advantages over their traditional counterparts. These include better control over the carbonization process, resulting in a more consistent product. Additionally, they are designed to reduce the emission of smoke and other pollutants, contributing to a cleaner production process.

Choosing the Right Charcoal Kiln

Selecting the appropriate charcoal kiln involves considering the scale of production and the specific requirements of the charcoal maker. Factors such as feedstock type, desired production capacity, and space considerations will influence the choice of a lump charcoal kiln or a more compact solution like an oil drum charcoal kiln. It is essential to assess the features of each kiln type to determine the most suitable option for efficient and effective charcoal production.

Conclusion

For those in the market for a charcoal production kiln, a comprehensive range of options is available to meet various production needs. While exploring the selection, it is crucial to consider the specific requirements of your operation to ensure the chosen kiln aligns with your production goals and material preferences. The right kiln can significantly enhance the efficiency of your charcoal production process.