Introduction to Cardboard Corner Cutters

Cardboard corner cutters are essential tools in the paper production and packaging industry, designed to precisely trim the corners of cardboard materials. These devices play a crucial role in preparing cardboard for various applications, ensuring a professional and neat finish for the final product.

Types and Applications

The versatility of cardboard corner cutters allows them to be utilized across multiple sectors. From small-scale operations such as local packaging businesses to larger entities like hotel chains and manufacturing plants, these machines streamline the production of toilet papers, napkins, paper cups, and other paper goods. The adaptability of these cutters means they can be integrated into various stages of paper processing, enhancing efficiency and productivity.

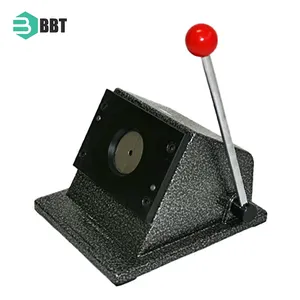

Features and Technical Specifications

A typical cardboard edge protector cutter includes several functional units such as embossing, slitting, and folding. These machines may feature different embossing patterns, achieved through steel-to-steel or steel-to-rubber mechanisms. With options ranging from compact models to larger industrial units, these cutters are designed to meet diverse production needs. Smaller units might have a production capacity of 70 to 80 pieces per minute, while larger machines can handle up to 3 tons of material per day.

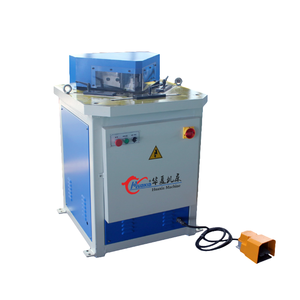

Automation and Control Systems

Modern cardboard corner cutters are often equipped with advanced automation features. These include photoelectric monitoring for operational precision and PLC control panels for seamless automation. The integration of automatic oil lubrication systems and pneumatic systems, operated by air compressors, further enhances the machine's performance and reliability.

Materials and Construction

The construction of a cardboard corner cutter typically involves robust materials that ensure durability and consistent operation. The choice of materials also influences the machine's weight, which can be a consideration for space and logistics planning within a facility.

Advantages of Using Cardboard Corner Cutters

Utilizing a cardboard corner cutter in production lines brings several advantages, including improved speed and accuracy in cardboard cutting. The automated systems reduce manual labor and potential errors, leading to a more streamlined manufacturing process. Additionally, the precision of these machines contributes to a reduction in material waste, which can translate to cost savings and environmental benefits.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4