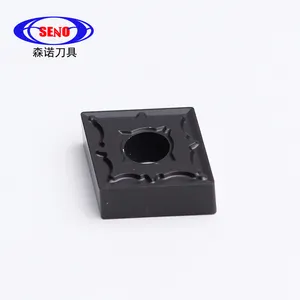

Introduction to Carbide Inserts

Carbide inserts are a pivotal component in modern machining, offering precision and durability. As a carbide inserts manufacturer in Israel, the focus is on producing inserts that meet the diverse needs of various machining operations. These inserts are crafted from robust materials, ensuring they maintain their hardness even at elevated temperatures, which is essential for high-speed cutting applications.

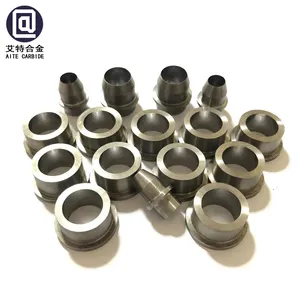

Types and Applications

There is a multitude of carbide insert types available, each designed for specific applications. From lathe turning tools suitable for cutting and radial grooving to specialized inserts for woodturning lathes, the versatility is evident. These tools are indispensable for operations such as sanding, drilling, deformation, and precision turning, enabling the creation of symmetrical objects with ease.

Features and Materials

The materials used in the production of carbide inserts are selected for their strength and thermal resilience. The robust nature of these materials contributes to the inserts' ability to retain sharpness and resist wear. The design of these tools often includes features that allow for easy adjustment, facilitating quick changes in location and depth during machining processes.

Advantages of Professional Tools

Opting for professional-grade carbide inserts from a reputable carbide inserts supplier is a step towards efficiency and precision in machining. Unlike homemade alternatives, these professional tools are designed for consistent performance and are easily adjustable to cover various dimensions, simplifying the process of cutter changes.

Selection and Availability

Choosing the right carbide insert involves considering the specific requirements of the task at hand. A wide selection of carbide inserts is available, each designed to meet different operational demands. The availability of various shapes and sizes ensures that there is a tool for almost every machining need.

Conclusion

For those in search of a carbide inserts manufacturer in Israel, the market offers a range of options to suit any project size, from large to medium. The emphasis on material quality and tool design ensures that these inserts provide reliable performance for a vast array of machining operations. By selecting the appropriate carbide insert, machinists can achieve the desired outcome with precision and efficiency.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4