Popular in your industry

Related Searches:

Top categories

About cable tie moulds

Introduction to Cable Tie Moulds

Cable tie moulds are specialized tools used in the production of cable ties, an essential component for bundling and securing wires and cables. These moulds are designed to shape and solidify plastic into durable cable ties through a process known as cable tie injection molding. The precision of these moulds determines the quality and reliability of the final product, making them a critical investment for manufacturers in the electrical and networking industries.

Types and Applications

There are various types of cable tie moulds available, each serving a specific purpose. From standard nylon cable ties to heat-resistant varieties, the moulds vary based on the type of cable tie they produce. The application of these cable ties spans across numerous sectors, including electronics, automotive, construction, and packaging. The design of the mould is tailored to the application, ensuring that the cable ties meet the required specifications and strength.

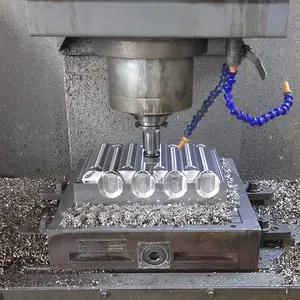

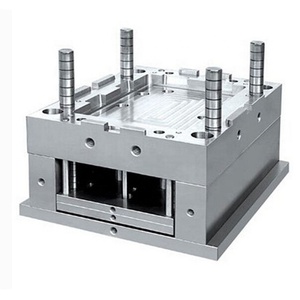

Features and Materials

The features of cable tie moulds include precision-engineered cavities and cores, which are essential for producing consistent and defect-free cable ties. Materials used in mould construction range from hardened steel to aluminum, with each offering different benefits in terms of durability and heat dissipation. The choice of material for a cable tie mould often depends on the projected production volume and the specific requirements of the cable tie being manufactured.

Advantages of Quality Mould Design

A well-designed cable tie mould can significantly enhance production efficiency. By incorporating features like standardized lift bars and clamp slots, moulds can be easily integrated into various cable tie injection molding machines, streamlining the manufacturing process. Additionally, a robust mould design can reduce cycle times and minimize waste, leading to cost-effective production without compromising on the quality of the cable ties.

Selection Considerations

Selecting the right cable tie moulds involves considering the type of injection molding machine in use, the material of the cable ties, and the desired production capacity. It is crucial to choose a mould that is compatible with the machinery and materials to ensure optimal performance and longevity of the mould. Suppliers on Alibaba.com offer a diverse range of moulds to meet these varied needs, providing valuable information to aid in the selection process.

Optimizing Production with Cable Tie Moulds

Incorporating the right cable tie moulds into your production line can lead to improved product quality and operational efficiency. By leveraging the vast selection available on Alibaba.com, businesses can find moulds that align with their production goals and requirements. It is advisable to engage with suppliers who can provide insights into the compatibility and performance of their moulds with your existing cable tie injection molding machine, ensuring a seamless production process.