Popular in your industry

Related Searches:

Top categories

About aerofoil profile

Aerofoil Profile: An Overview

An aerofoil profile is a versatile component widely utilized in various industrial sectors. This profile, characterized by its aerodynamic shape, is primarily designed to manage airflows in numerous applications. The aerofoil's unique design allows it to be effective in both high-speed and low-speed environments, making it a critical element in construction, office furniture design, interior aesthetics, and even in the automotive industry.

Types and Shapes of Aerofoil Profiles

The array of shapes available for aerofoil profiles is extensive, catering to diverse industrial needs. These profiles come in several forms, such as L-angled, square, and T-shaped bars, each serving a specific function. Hollow tubes and solid round tubes are also common, providing structural support where needed. Additionally, specialized shapes like J caps, Z clips, and channels are integral to the assembly of complex systems, including sliding tracks and framing systems.

Material Specifications and Surface Treatments

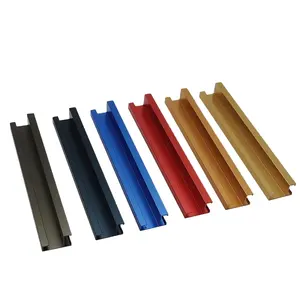

Aerofoil profiles are predominantly made from aluminum alloys, particularly the 6000 series, known for their balance of strength and workability. The temper of these profiles can range from T3 to T8, indicating the level of hardness and strength due to heat treatment. Surface treatments for these profiles are diverse, including options like powder coating, anodizing, and sandblasting. Each treatment offers a different aesthetic and protective quality, from the sleek, reflective finish of electrophoresis to the rustic appeal of wood grain textures that mimic real wood.

Applications and Features

The application of aerofoil profiles is broad, spanning across various fields. In construction, their aerodynamic shape is crucial for creating elements that can withstand environmental forces. For office furniture, these profiles contribute to ergonomic designs that enhance comfort and productivity. In the realm of lighting fixtures, the profiles are engineered to support the aesthetics and functionality of the design. The automotive sector also relies on these profiles for parts that require a balance of lightweight design and structural integrity.

Advantages of Using Aerofoil Profiles

Employing aerofoil profiles in projects comes with a multitude of advantages. Their aerodynamic shape is engineered to reduce drag and improve efficiency, which is paramount in automotive and aerospace applications. The versatility in shapes and materials also allows for customization to meet specific design requirements. Furthermore, the durability of materials like the 6000 series aluminum alloy ensures longevity and resistance to corrosion, especially when combined with appropriate surface treatments.

Customization and Variety

Customization is a key aspect of aerofoil profiles, with suppliers offering to tailor dimensions and thicknesses to client specifications. The surface finish can also be customized, ranging from matte to glossy, and from monochromatic to a spectrum of colors. This flexibility ensures that the profiles can be adapted to the aesthetic and functional demands of any project.