Popular in your industry

Related Searches:

Top categories

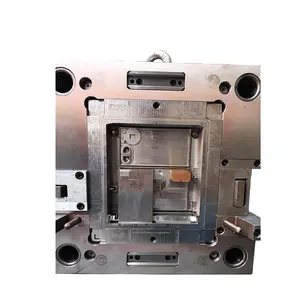

About 500ml plastic bottle mould mold

Introduction to 500ml Plastic Bottle Moulds

The 500ml plastic bottle mould mold is a pivotal component in the production of plastic bottles, serving a diverse range of industries. These molds are designed to shape plastic into half-liter bottles that are commonly used for beverages, cleaning agents, and personal care products. The versatility of these molds allows for the creation of bottles that meet specific requirements, including durability, design, and material composition.

Types and Applications

There are various types of injection molding tools tailored for the production of 500ml bottles. These range from single-cavity molds for bespoke or small-scale production to multi-cavity molds for larger outputs. The application of these molds extends across sectors such as food and beverage, pharmaceuticals, and consumer goods, highlighting their importance in daily logistics and product delivery.

Material and Features

The materials used in the construction of plastic injection molds are selected for their strength and precision. Common materials include steel and aluminum, each offering distinct advantages in terms of durability and cost-effectiveness. Features such as cooling systems and ejection mechanisms are integral to the mold design, ensuring consistent quality and efficient production cycles.

Advantages of Standardization

Opting for a standardized 500ml bottle blow mold can significantly reduce production costs and increase operational efficiency. Standardization of elements like lift bars and clamp slots ensures compatibility with different machinery, facilitating seamless manufacturing processes. This approach not only simplifies the production but also enhances the interchangeability of mold components.

Selection Considerations

When selecting a 500ml PET bottle mold, it is crucial to consider the mold's compatibility with the intended injection molding machine and the type of plastic material to be used. The design intricacies, such as the neck finish and bottle thickness, are also vital factors that influence the final product's functionality and aesthetic appeal.

Collaboration with Suppliers

Collaborating with suppliers on Alibaba.com for a custom plastic bottle mold involves discussions around design specifications and material choices to ensure the mold meets the desired requirements. Suppliers offer expertise in refining mold designs, conducting trials, and making necessary adjustments for optimal mold performance without making definitive guarantees on the outcomes.