Understanding the 3 Axis Table

A 3 axis table is an integral component in various machining and manufacturing processes. This versatile equipment can perform precise movements along three different axes, X, Y, and Z, which allows for intricate and detailed work on a range of materials.

Types of 3 Axis Tables

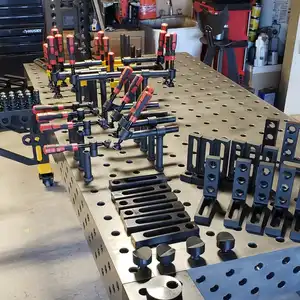

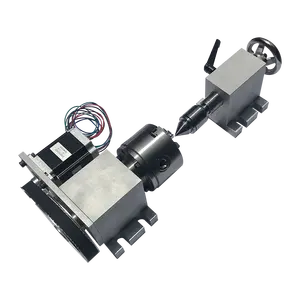

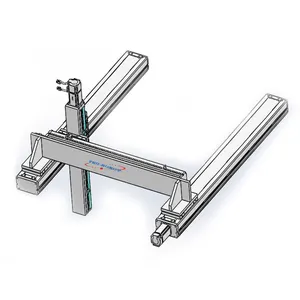

The world of 3 axis tables is diverse, with each type catering to specific needs. The 3 axis milling table is designed for precision machining, suitable for tasks that require complex geometries and surfaces. In contrast, a 3 axis router table is typically used in woodworking and metalworking for cutting, engraving, and shaping. For those requiring rotational movement, the 3 axis rotary table is an ideal choice, enabling users to work on a piece from various angles without repositioning.

Applications and Features

The application of a 3 axis CNC table spans across industries from aerospace to automotive, where precise and repeatable movements are paramount. These tables are equipped with features such as self-lubricating components to enhance longevity and performance. The 3 axis positioning table, a variant within this category, is specifically designed for tasks that require high levels of accuracy in positioning and alignment.

Materials and Advantages

Materials used in the construction of 3 axis tables are selected based on their durability and wear resistance. This ensures that the tables can withstand the demands of heavy loads and continuous operation. The advantage of using a 3 axis CNC router table includes its ability to maintain precision over long periods, thereby reducing the need for frequent maintenance and potential downtime.

Choosing the Right 3 Axis Table

Selecting the right 3 axis table involves understanding the specific requirements of your application. Considerations such as load capacity, orientation, and the type of slide bearings—whether plain bearing slides for heavy-duty applications or ball bearing slides for lighter tasks—will inform your choice. Ensuring compatibility with your existing systems and operations is crucial for seamless integration.

Conclusion

A 3 axis table is a foundational tool for businesses requiring precision and versatility in their operations. While exploring options, it is essential to assess the specifications and features that align with your operational needs. A well-informed selection will contribute to the efficiency and quality of your production processes.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4