Understanding the intricacies of silk screen mesh price per meter is crucial for businesses looking to procure materials for screen printing. This product is a staple in the printing industry, where precision and quality are paramount. The silk screen mesh is available in various specifications, including different materials like polyester and nylon, and a range of colors such as white, yellow, and combinations of white and yellow.

Types and Characteristics of Silk Screen Mesh

Diving deeper into the types of silk screen mesh, businesses will find a spectrum of options tailored to specific printing needs. The mesh count, which can range from a coarse 80 to a fine 300, directly affects the amount of ink that passes through and the detail level achievable on the printed substrate. A lower mesh count is ideal for bold prints on banners or t-shirts, where a higher volume of ink is desirable. Conversely, a higher mesh count is perfect for intricate designs on electronics or glassware, where precision is key. The thread diameter also varies, with thinner threads allowing for a higher mesh count and finer printing. This variation in mesh types ensures that whether a business is printing solid block colors or detailed graphics, there is a suitable mesh available.

Structure of Silk Screen Mesh

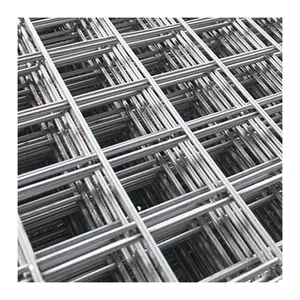

The structure of silk screen mesh is a testament to the precision engineering required in screen printing. Each mesh is meticulously woven and then stretched over a frame, which can be made from various materials such as wood or aluminum. The tension must be evenly distributed to prevent any distortion during the printing process. The frame serves as the backbone, providing a sturdy base for the mesh. The mesh itself acts as a sieve, with its fine pores allowing ink to pass through only in the desired areas. This structure is pivotal in ensuring that each print is sharp and that the screen can be used repeatedly without a loss in print quality.

Materials and Their Properties

The materials used in silk screen meshes are selected for their tensile strength and durability. Polyester is favored for its exceptional durability, resistance to chemicals, and minimal moisture absorption, which ensures that the screen tension remains stable over time. Nylon, known for its elasticity, is particularly useful for printing on uneven surfaces as it can adapt to slight contours. These materials are not chosen at random; their properties are carefully considered to provide the best outcome for the print's intended purpose. For instance, the resilience of polyester makes it an excellent choice for high-volume runs, while nylon's flexibility is perfect for specialty prints on surfaces that are not perfectly flat.

Business Usages and Applications

The business usages of silk screen mesh are diverse, spanning across various sectors. In the textile industry, it's used to create vibrant designs on clothing and accessories. In the realm of advertising, it's employed to produce sharp, durable banners and signage. The electronics industry relies on it for the precise application of conductive inks in circuit board production. Each application benefits from the mesh's ability to deposit ink consistently, which is crucial for maintaining brand standards and functional requirements. The adaptability of silk screen mesh to different inks and substrates makes it an invaluable tool in commercial and industrial settings.

Functions of Silk Screen Mesh

The function of silk screen mesh goes beyond simply acting as a barrier for ink. It is engineered to provide a precise degree of control over the deposit of ink onto the substrate. The mesh's function is to hold the stencil in place and to allow the squeegee to push ink through the mesh openings in the desired pattern. This precise control enables multi-layered prints, intricate details, and consistent results that are crucial for professional-grade screen printing.

Features of Silk Screen Mesh

The features of silk screen mesh that set it apart include its uniform weave, which ensures even ink distribution, and its ability to be reused for multiple prints without degradation in quality. These features are critical for businesses that require consistent branding and high-quality prints. The mesh's durability means that it can withstand the rigors of the printing process, including the pressure of the squeegee and the repeated application of inks.

Benefits of Silk Screen Mesh

The benefits of using a high-quality silk screen mesh are numerous. For businesses, the primary advantage is the mesh's contribution to producing sharp, clear prints that reflect well on the quality of the products. Additionally, the longevity of materials like polyester and nylon translates to cost savings, as the mesh does not need to be replaced as frequently as inferior alternatives. This durability also means less downtime in production, as screens do not need to be re-stretched or repaired as often, leading to increased productivity.

How to Use and Maintain Silk Screen Mesh

Proper use of silk screen mesh involves ensuring that the screen is correctly aligned with the substrate before printing begins. The mesh should be inspected for any signs of damage or wear, as even small imperfections can affect print quality. Maintenance is straightforward but essential; after each print run, the mesh should be cleaned with a suitable solvent to remove any residual ink. This cleaning prevents clogging and maintains the sharpness of future prints. Additionally, the mesh should be stored in a clean, dry environment to prevent any damage or distortion.

Choosing and Installing the Right Silk Screen Mesh

Choosing the right silk screen mesh involves considering the specific requirements of the print job. Factors such as ink type, substrate material, and the level of detail in the design all play a role in selecting the appropriate mesh count and material. Installation of the mesh onto the frame must be done with care to ensure even tension, which is critical for maintaining print accuracy. A properly installed mesh will not sag or ripple, which could otherwise lead to an uneven print.

Target Audience and Meeting Their Needs

The target audience for silk screen mesh includes businesses in the screen printing industry that demand precision and reliability in their printing processes. This includes small boutique print shops that specialize in custom work, as well as large-scale industrial printers. The product meets the needs of these diverse audiences by offering a range of mesh counts and materials, ensuring that whether the task is fine art reproduction or printing of industrial-grade circuit boards, there is a silk screen mesh suitable for the job.

Exploring the silk screen mesh price per meter on Alibaba.com provides businesses with a comprehensive understanding of the product's attributes and its role in the screen printing process. The platform's vast selection ensures that buyers can find the right mesh to meet their specific printing requirements.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4