Introduction to Plug Making Machines

Plug making machines are essential in the manufacturing sector, serving as the backbone for producing various types of plugs used in multiple industries. These machines are adept at handling different materials to create plugs that meet specific industry standards. With a focus on the plastic plug making machine, this category encompasses a range of equipment designed to shape plastic granules into precise plug dimensions.

Types and Applications

The versatility of plug making machines allows for the production of a wide array of plug types. From electric plug making machines that cater to the electrical industry to wood plug making machines and wooden wall plug making machines, these units are tailored to meet diverse manufacturing needs. The spark plug making machine is another specialized type, specifically designed for the automotive sector. These machines are not just limited to creating simple plugs; they are also capable of producing complex wall plug manufacturing machine components for construction and home fittings.

Features and Materials

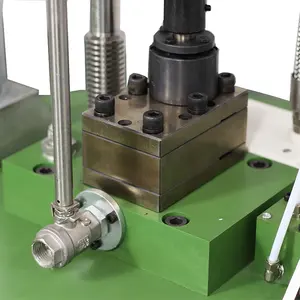

Modern plug making machines are engineered to handle various materials with precision. The plastic wall plug making machine, for instance, is equipped with a special screw that enhances plasticizing capabilities, ensuring efficient and accurate production. The construction of these machines often involves robust materials that contribute to their longevity and consistent performance, even when subjected to the high demands of plug production.

Advantages of Modern Plug Making Equipment

Investing in a state-of-the-art plug making machine means benefiting from advanced features like a single-cylinder system with a servo-valve, which aids in achieving a swift response rate during operation. The clamping force of these machines is another highlight, with a range that can withstand significant external machining forces, ensuring the production of plugs with consistent quality and dimensions.

Design and Durability

The design of plug making machines is focused on durability and efficiency. For example, the steel bush in the clamping unit of these machines is constructed to minimize wear resistance, which in turn reduces the need for frequent lubrication, offering cost savings on maintenance. The precise clamping force design ensures that the machine meets the exact requirements of the production process, enhancing the overall efficiency and output quality.

Choosing the Right Machine

Selecting the appropriate plug making machine for your business involves considering the specific requirements of your production line. Whether you need a wall plug making machine price-conscious option or a high-capacity model for larger scale production, Alibaba's platform connects you with a diverse range of machines to suit your needs. By browsing the listings, you can find the right equipment to shape your plastic processing business's future without the need for direct brand endorsements or promotional guarantees.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4