Popular in your industry

Related Searches:

Top categories

About hot stamping date coding machine

What is Date Coding Machine For Hot Stamping

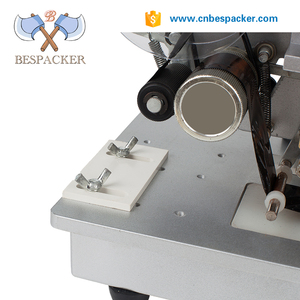

Date coding machines for hot stamping are a type of equipment used to imprint variable information, such as expiration dates, batch numbers, or production dates, onto various products and packaging materials. These machines are essential for manufacturers, packaging companies, and businesses that require the marking of their products to comply with industry regulations and standards, ensuring traceability and accountability in the production and distribution processes.

The principle behind date coding machines involves the transfer of heat and pressure through a metal plate or type, which is heated to a specific temperature and then pressed onto the product's surface. The heat and pressure cause the machine's specially designed dies to combine with a foil or film, transferring the coded information onto the product. This process is not only fast but also highly precise, allowing for clear and permanent markings that are crucial for tracking and quality control.

These machines are designed with various features to accommodate different production needs, including adjustable temperature settings, pressure control, and the ability to switch between coding types such as alphanumeric characters, expiry dates, or barcodes. Advanced models may also offer features like automatic foil feeding, length adjustment, and even the capability to store multiple stamping designs for quick changes between production runs.

Types of Date Coding Machine for Hot Stamping

Date coding machines for hot stamping are available in various types to suit different applications and production scales:

-

Manual Date Coding Machines: These are small, handheld devices that provide flexibility for users to stamp dates on products using a heated die. They are often used in smaller production runs or by businesses with a limited number of products that require date tracking.

-

Semiautomatic Date Coding Machines: These machines require some manual operation, such placing the product under the heated die and then lowering it onto the inked date. They are suitable for medium-sized production runs where the process can be semi-automated.

-

Automatic Date Coding Machines: Designed for high-volume production, automatic date coding machines can quickly and consistently stamp dates on products without the need for manual intervention. These are ideal for large manufacturing plants where efficiency is crucial.

Each type has common use cases ranging from food packaging to pharmaceutical labeling and is selected based on factors like production volume, space availability, and desired level of automation.

How to choose Date Coding Machine For Hot Stamping

Selecting the right Date Coding Machine for Hot Stamping involves considering the type of material you'll be working with, the desired quality of the print, the required speed, and the environmental conditions in which the machine will operate. When evaluating options for your business on Alibaba.com, here are some key points to consider:

-

Material Compatibility: Ensure that the machine is capable of printing on the material of your product. For example, if you're marking on flexible packaging or labels with a plastic substrate, a thermal transfer overprint coder may be suitable.

-

Print Quality: Hot stamping machines can produce high-resolution prints suitable for detailed information such as expiry dates or barcodes. Consider what type of information you need to convey and how legible it needs to be.

-

Speed Requirements: The machine's output should match your production speed requirements. Look for machines capable of producing the necessary number of imprints per minute (IPM) without compromising on quality.

-

Environmental Conditions: Some machines are designed to withstand harsher environments with dust or moisture; consider the operating conditions of the machine.

-

Integration Compatibility: The chosen machine should be able to integrate seamlessly into your existing production line.

By keeping these considerations in mind when browsing Alibaba.com's extensive selection of Date Coding Machines for Hot Stamping, businesses can make informed decisions that align with their operational needs and quality expectations.

About Date Coding Machine For Hot Stamping on Alibaba.com

Alibaba.com stands as a global marketplace connecting buyers with suppliers offering a vast selection of date coding machines suitable for various industries. With its comprehensive range of products catering to different printing methods like hot stamping, this platform simplifies the sourcing process for businesses worldwide. Alibaba.com provides an extensive collection from verified suppliers ensuring that businesses can find machines meeting their specific needs without compromising on quality or reliability.

The platform’s user-friendly interface allows businesses to filter through options based on features such as printing area size, power source, and applicable industries. This streamlines the selection process, enabling businesses to find machines that will deliver precise and efficient date coding solutions. Furthermore, Alibaba.com’s Trade Assurance service offers peace of mind by protecting payments until orders are fulfilled satisfactorily.

Alibaba.com’s commitment to facilitating easy international trade is evident through its multilingual support and mobile-friendly buying options. This makes it easier than ever for businesses to access cutting-edge technology that can help them stay competitive in a fast-paced market. Whether you're looking to improve traceability in your food packaging or streamline your manufacturing processes with reliable date coding solutions, Alibaba.com is poised to be your go-to platform for wholesale date coding machines.

Common FAQs for Date Coding Machine For Hot Stamping

What is a date coding machine used for in industrial settings?

Date coding machines are used in various industrial applications to mark expiration dates on products and packaging. They ensure that customers receive products that are fresh and safe to use within a reasonable timeframe.

How does a date coding machine work?

Date coding machines typically use hot stamping or thermal transfer printing technologies to apply a permanent mark onto products or packaging materials using heated printing methods.

Can a date coding machine be used on all types of packaging materials?

Most date coding machines can be used on a variety of packaging materials including paper, plastic, aluminum foil, and more. However, it's important to select a machine that is compatible with the specific material of your packaging needs.

Is it possible to change the date format on a date coding machine?

Yes, date coding machines often come with options to change the date format. This can be done through the machine's control panel or software, depending on the model.

Do date coding machines require special consumables or can they work with generic options?

These machines are designed to work with specific consumables such as ink, hot foil, or thermal transfer ribbons. It's important to ensure that the consumables are compatible with your machine's specifications.

What factors should be considered when choosing a date coding machine for a specific industry?

When selecting a date coding machine, consider the types of materials you'll be marking, the desired font and format of the printed date, the speed at which you need to operate the machine, and any additional functionalities that could benefit your operations.

How do I ensure consistent and legible date codes on my products?

Consistency and legibility are ensured by using high-quality machines with appropriate settings for the substrate and ink type. Regular maintenance checks and updates are also recommended.

Are there portable options for date coding machines?

Yes, there are handheld and portable date coding machines available that are ideal for situations where mobility is necessary or where space is limited. These options offer convenience and flexibility for various applications.

Can multiple date codes be printed on a single product?

Yes, some date coding machines have the capability to print multiple date codes on a single product. This is particularly useful for products that require information regarding different stages of production or distribution.

What maintenance is required for a date coding machine?

Regular maintenance for a date coding machine includes cleaning the printhead, ensuring there is sufficient ink in the system, updating software when necessary, and checking for any physical wear on parts.

How does a hot stamping machine differ from a thermal transfer printer?

A hot stamping machine uses a heated die to apply foil or transfer a colored coating onto a surface using a printing process, which is different from a thermal transfer printer that uses heat to transfer ink directly onto a surface.

Is it possible to integrate a date coding machine with existing production lines?

Many date coding machines can be integrated with existing production lines as long as they are compatible with the materials and packaging types of the operation. It's important to consult with the manufacturer before attempting integration.

What should I look for if I need a versatile date coding machine that can handle different types of packaging?

Look for a date coding machine with adjustable settings that can accommodate various packaging sizes and materials. Flexibility is key for machines that need to handle multiple types of products or packaging.