Introduction to Cold Feed Rubber Extruders

Cold feed rubber extruders are essential equipment in the rubber processing industry, designed to handle various rubber compounds without the need for pre-heating. These machines are pivotal for businesses looking to streamline their manufacturing processes, offering a blend of precision, efficiency, and versatility. With a significant share in the market, these extruders cater to a broad spectrum of industrial applications.

Types and Configurations

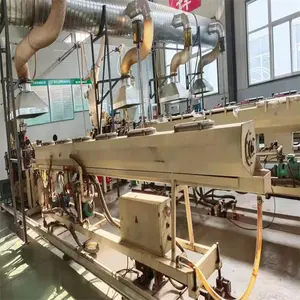

The versatility of cold feed extruders is evident in their various types and configurations, each tailored to meet specific production requirements. From basic single-screw designs to advanced twin-screw systems, the selection caters to different levels of complexity and output needs. The choice of an extruder depends on the material characteristics and the desired end product, ensuring that every manufacturing plant can find a suitable match for their operations.

Applications and Features

Cold feed extrusion technology is widely employed in creating a range of rubber products, from automotive parts to construction materials. These extruders boast features such as enhanced feed mechanisms and sophisticated control systems, which contribute to their ability to produce with high accuracy. The absence of a warm-up phase reduces energy consumption, while the precision of the equipment ensures consistent product quality.

Materials and Advantages

Constructed to handle a variety of rubber materials, cold feed rubber extruders are compatible with synthetic rubber, natural rubber, and silicone, among others. The advantages of using a cold feed extrusion machine include improved material properties due to less heat exposure and reduced operational costs. Moreover, the cold feed process enhances safety by minimizing the risks associated with handling hot materials.

Operational Excellence

Operational excellence is at the forefront of rubber extrusion machinery. These units are engineered to operate with high efficiency, ensuring that production lines maintain a steady flow. The integration of modern control systems, such as PLCs, allows for precise operation and monitoring, which is crucial for maintaining the quality of the extruded products.

Choosing the Right Extruder

Selecting the right cold feed rubber extruder is a critical decision for any manufacturing operation. Factors such as the type of rubber, the complexity of the extruded shapes, and the production volume all play a role in determining the most suitable machine. While Alibaba.com does not endorse any particular brand or model, the platform facilitates the connection between buyers and a diverse array of suppliers, ensuring that every business can find the equipment that meets their specific needs.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4