Introduction to Automatic Aluminum Cutting Machines

The realm of metal fabrication has been revolutionized by the advent of automatic aluminum cutting machines. These machines are engineered to enhance precision and efficiency in cutting aluminum and other metals. They are pivotal in industries where metal components with exact specifications are crucial.

Types and Applications

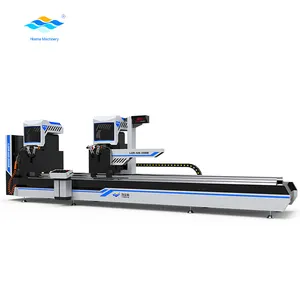

Automatic aluminum cutting machines come in various types, each suited to specific tasks and materials. From laser-powered systems, which are ideal for intricate cuts and fine detailing, to blade-based models that handle larger, more robust cutting jobs, the versatility of these machines is vast. They are commonly employed in industries such as automotive, aerospace, and construction, where they are instrumental in producing components like frames, panels, and structural elements.

Features and Technical Specifications

The technical prowess of an automatic aluminum cutting machine is evident in its features. These include automated pipe loading, water cooling systems, and advanced control systems like PLC or CNC for precise operations. The cutting capabilities of these machines vary, with thicknesses ranging typically from 5mm to 20mm and cutting diameters from 6mm to over 220mm for larger models. Speed is also a hallmark of these machines, with some reaching cutting speeds up to 8,000mm/s.

Materials and Advantages

While primarily designed for aluminum, these machines also adeptly cut other metals such as copper, stainless steel, carbon steel, and iron. The advantage of using an automatic aluminum cutting machine lies in its ability to maintain consistent quality and precision in cuts, whether the material is solid or hollow, round or square. The automation of these systems reduces manual labor, thereby minimizing fatigue and the potential for errors.

Operational Efficiency

Operational efficiency is a key benefit of these cutting machines. The integration of computer systems allows for the cutting of complex shapes with minimal human intervention, streamlining the production process. This efficiency is not only in the shape and precision of cuts but also in the use of time and resources, making the automatic aluminum cutting machine a valuable asset in any metalworking facility.

Choosing the Right Machine

Selecting the right automatic aluminum cutting machine requires a thorough understanding of one's production needs and the materials to be cut. Factors such as cutting capacity, speed, and the type of control system play a significant role in the decision-making process. While Alibaba.com does not endorse any particular brand or model, the platform offers a comprehensive listing of machines from various global suppliers, allowing buyers to compare and choose based on their specific requirements.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4